- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Automatic Window Patching Machine

China’s automatic window patching machine has been the latest model pushed to market. Featured by its digital control, dual-use , speed , functionality, also cheap product and good service, it has been widely received all over the world. Get Factory Price from NEW STAR.

Model:TC-850A

Send Inquiry PDF DownLoad

The Chinese NEW STAR machine is a firm which manufactures and sells Automatic window patching machine equipment and other printing processing equipment. Our Automatic window patching machine has been approved by both domestic customers and foreign customers. Let’s be your trusted Automatic window patching machine supplier in the new situation to create a better future. Get your instantquotation via email below.

Automatic window patching machine

Automatic window patching machine is a kind of equipment for window opening color box and color box film pasting. It is a relatively * model of window pasting machine in China at present* The humanized design idea makes this machine have high efficiency high-precision. High stability and simple operation.

Product Parameter (Specification)

|

Model |

TC-850A |

|

Max Paper |

580*850mm |

|

Min Paper |

100*100mm |

|

Paper Weight |

Kraft paper: 150-1200g/m2 |

|

White Cardboard: 230-1200g/m2 |

|

|

Corrugated Paper: ≤3mm |

|

|

Max Film |

L320*W350mm |

|

Min Film |

L50*W20mm |

|

Thickness Range |

0.038mm-0.25mm |

|

Max Diameter Film Unwinding |

400mm |

|

Paste Error |

±1.5mm |

|

Work Speed |

13000 pcs/h |

|

Quantity of Servo Motor |

2 sets (1 set of paper feeding part; 1 set of film feeding part) |

|

Quantity of Stepping Motor |

2 sets (1 set of automatic paper delivery, 1 set of knife holder left and right) |

|

Machine Size |

4600*1500*1600mm |

|

Power |

380/415V 50/60Hz 5.5KW |

|

Weight |

1.68ton |

Product Feature And Application

Automatic window patching machine is suitable for automatic window filming of window cartons such as tissue boxes, cosmetic boxes, gift boxes, clothing boxes, toy boxes, etc. Corrugated paper is also suitable, and special-shaped cartons are also easy to operate.

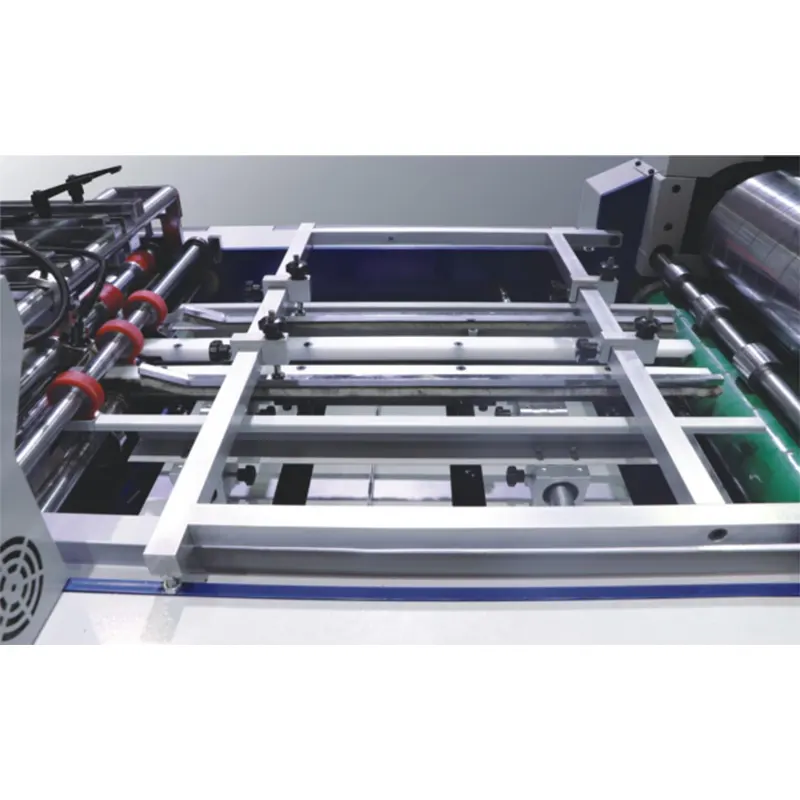

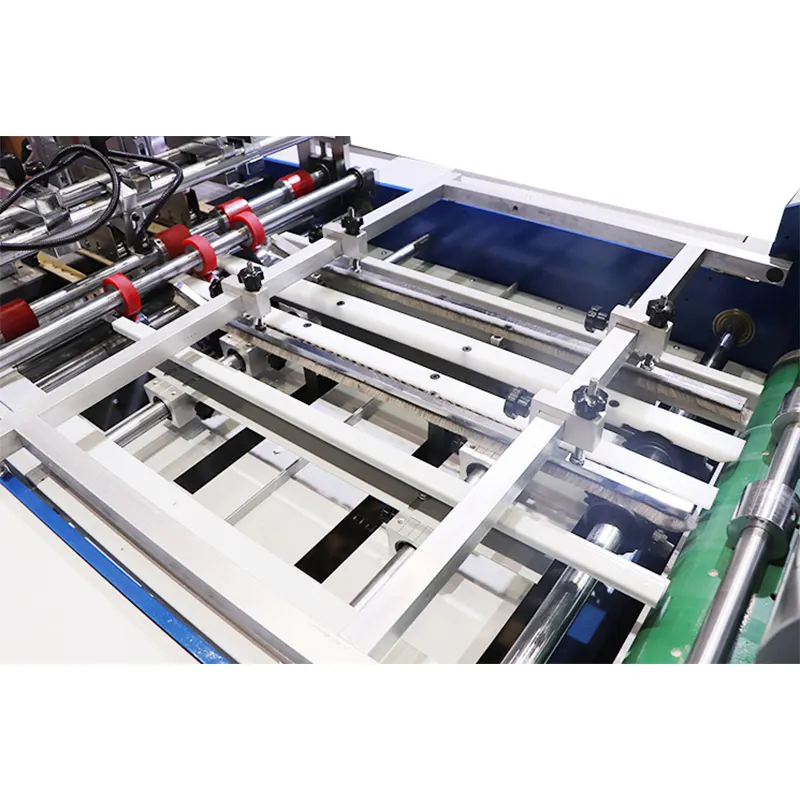

1.The paper conveying belt adopts the Japanese Nita brand and durable beef tendon belts, which can be selected according to product needs.

2. The bottom belt vacuum absorbs the paper and is driven by a servo motor, which can switch multiple paper feeding modes.

3. Touch screen operation panel is equipped with a "Inch, start, stop, speed adjust" quick operation button.

4. Chain guides are made of imported polymer materials, wear-resistant and mute, and paper positioning is made of square pushers to increase the stability of paper in high-speed operation.

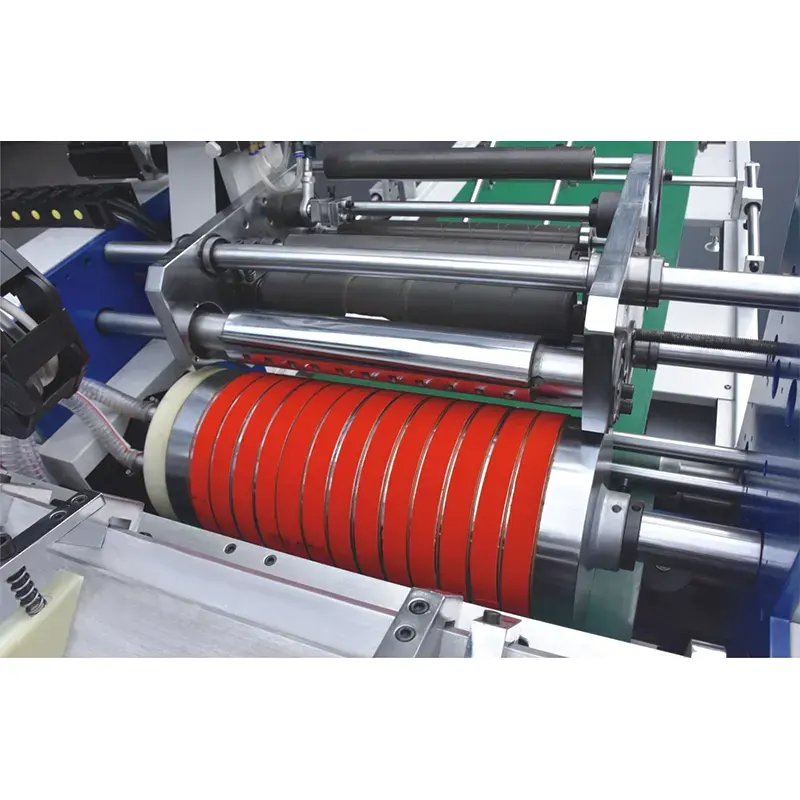

5. The special mechanical structure design applies the glue to the product surface quickly and evenly through the sponge gluing method, with good scraping effect.

6. The film feeding adopts servo motor transmission and roller adsorption for continuous pasting. Compared with the traditional intermittent pasting, it has the advantages of fast bonding speed, high precision, and low requirements on the film.

7. The delivery table uses a separate stepping motor to control the belt operation, the stacking distance can be adjusted as a whole or in sections, and it runs at multiple speeds. It can be continuous, paused, and points can be used flexibly.

8. The whole machine adopts full servo motion control, and various electrical components and detection switches are produced by companies in Japan, Taiwan, France, and Germany.

Product Details

|

1. Paper feeding section The paper conveying belt adopts the Japanese Nita brand and durable beef tendon belts, which can be selected according to product needs. If there are many UV products, you can choose Japanese Nita belts to solve the problem of uneven paper conveying. The bottom belt vacuum absorbs the paper and is driven by a servo motor, which can switch multiple paper feeding modes. |

2. Operating interface All the parameters and functions of the switch are operated in the touch screen, and the operation panel is equipped with a "Inch, start, stop, speed adjust" quick operation button. |

|

|

|

3. Positioning Department Chain guides are made of imported polymer materials, wear-resistant and mute, and paper positioning is made of square pushers to increase the stability of paper in high-speed operation. |

4. Glue department The special mechanical structure design applies the glue to the product surface quickly and evenly through the sponge gluing method, with good scraping effect. |

|

|

|

5. Film section The film feeding adopts servo motor transmission and roller adsorption for continuous pasting. Compared with the traditional intermittent pasting, it has the advantages of fast bonding speed, high precision, and low requirements on the film. |

6. Delivery station The delivery table uses a separate stepping motor to control the belt operation, the stacking distance can be adjusted as a whole or in sections, and it runs at multiple speeds. It can be continuous, paused, and points can be used flexibly. |

|

|

|

7. Electrical System The whole machine adopts full servo motion control, and various electrical components and detection switches are produced by companies in Japan, Taiwan, France, and Germany. |

|

|

|