- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

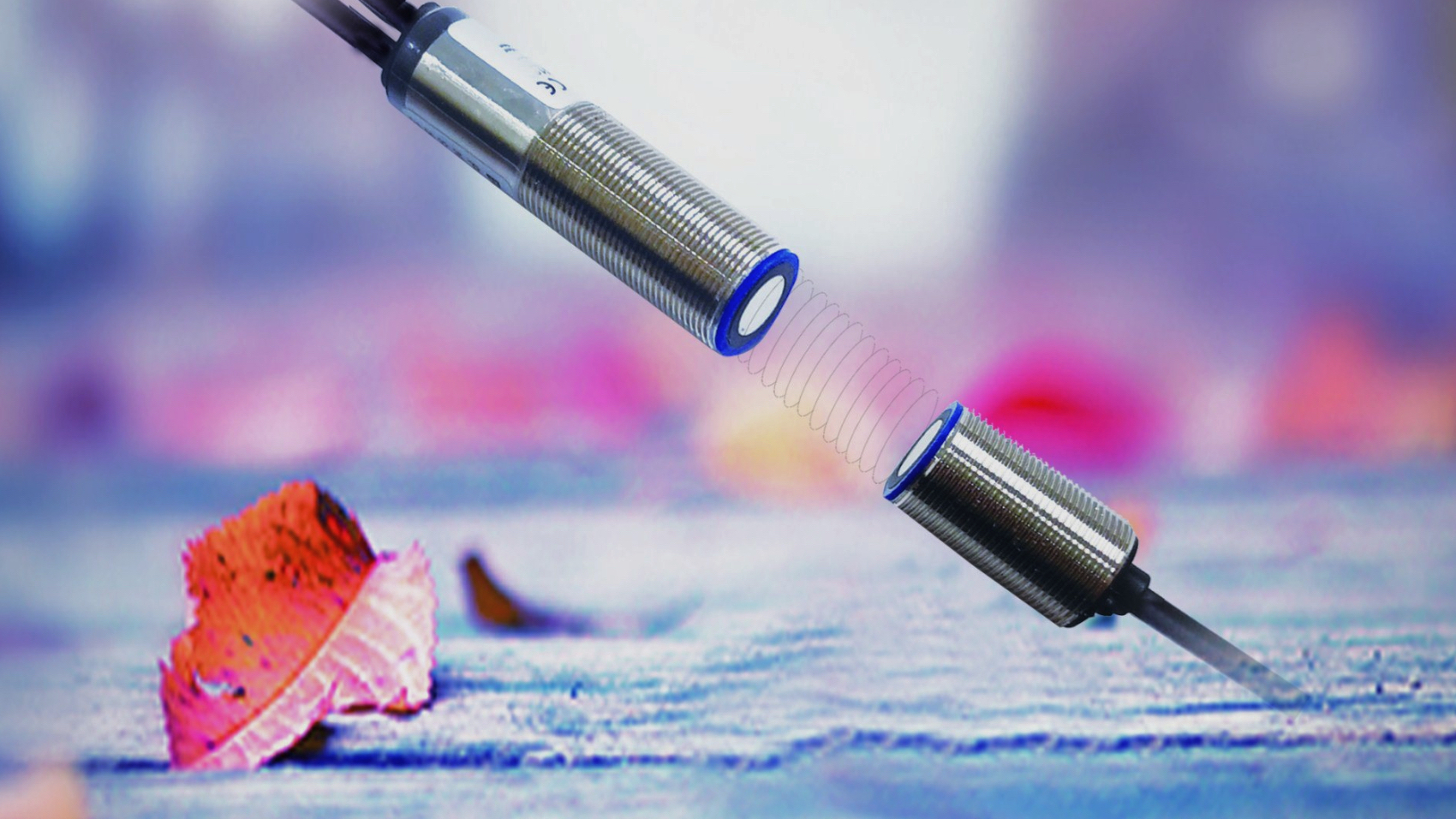

How Does the Double Sheet Detection Sensor Work?

In the process of automatic feeding, some objective factors will cause two or more sheets of materials to be stuck together, which will easily lead to waste of materials, unqualified products and equipment damage. The task of double sheet detection is to intelligently identify the situation of doubl......

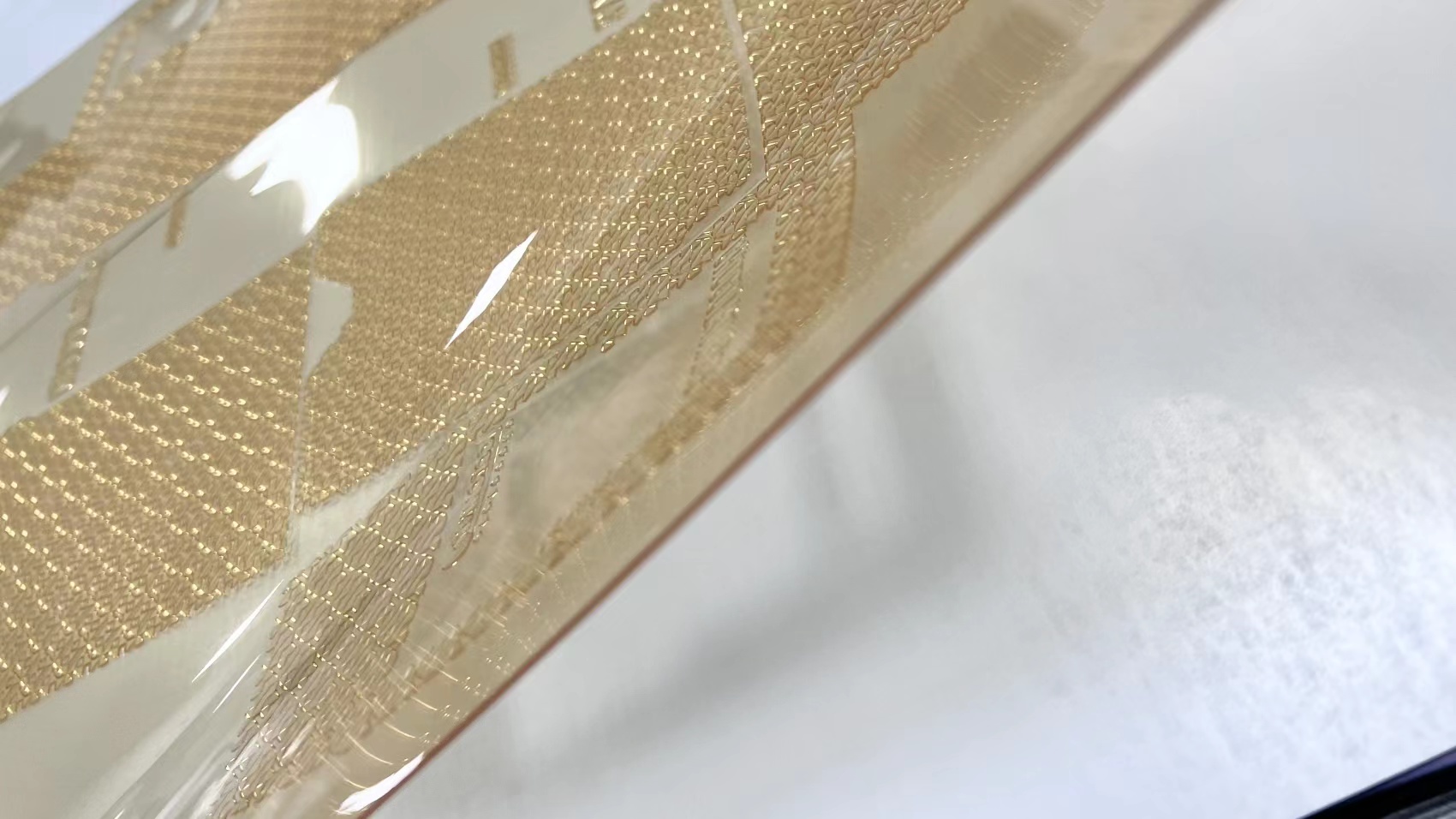

Read MoreDifferent Technical Requirements Between Single & Double Side Lamination

The difference between the technical requirements of single sided and double-sided film lamination lies in: 1. The surface temperature of single side coated metal steel roll in hot state is 8 ℃± 2 ° C, and the temperature of double side coated metal steel roll is generally controlled at about 50 ° ......

Read MoreIntroduction of Air Expansion Shaft - Film Loading Device

Air shaft is a special winding and unwinding shaft, that is, the shaft whose surface can protrude after high pressure expansion, and the shaft whose surface rapidly retracts after deflation is called expansion shaft. Its name is diversified, also called gas, expansion shaft, expansion roll, expansio......

Read MoreWhat Are the Methods of UV Coating?

The roller coating device is used to transfer the varnish to the surface of the carton. The coating amount and pressure of the coating unit are controlled by the printing machine control center. When working in the form of three roller reverse operation, the coating roller and the bucket roller oper......

Read MoreHow to Choose Laminating or UV Coating?

Today's printing plants and publishing houses pay much attention to UV technology and believe that UV coating can replace film laminating technology in book printing. In fact, this is just a wish of people. According to some printing plants applying UV coating technology, UV coating still has limita......

Read More