- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

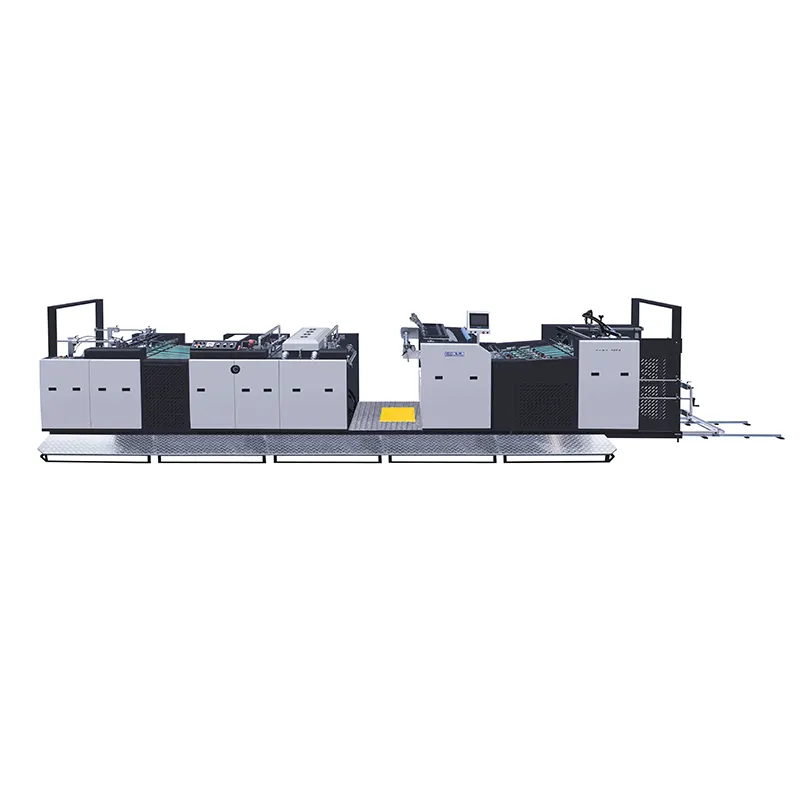

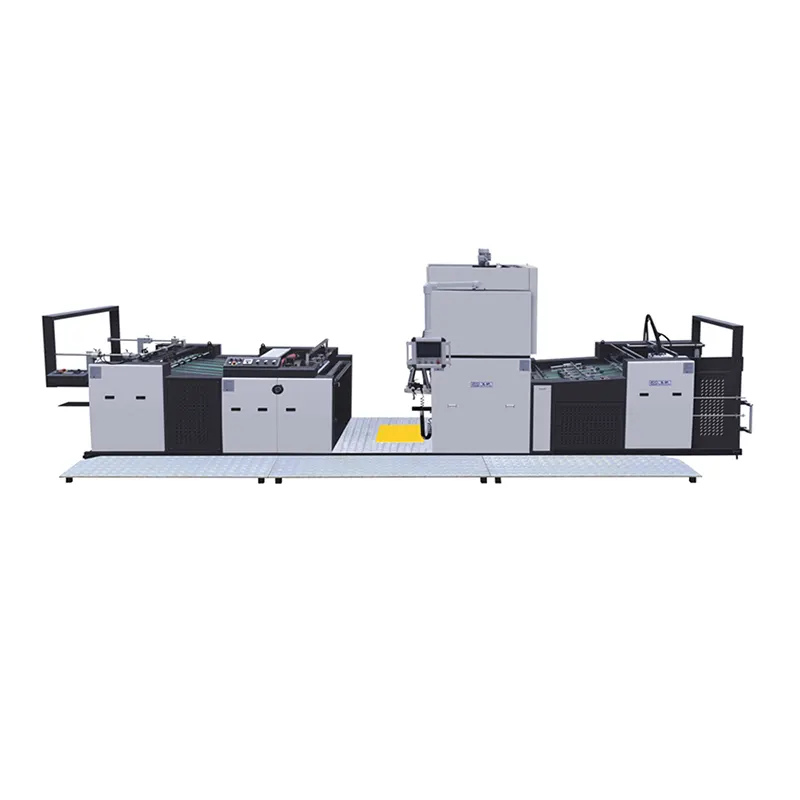

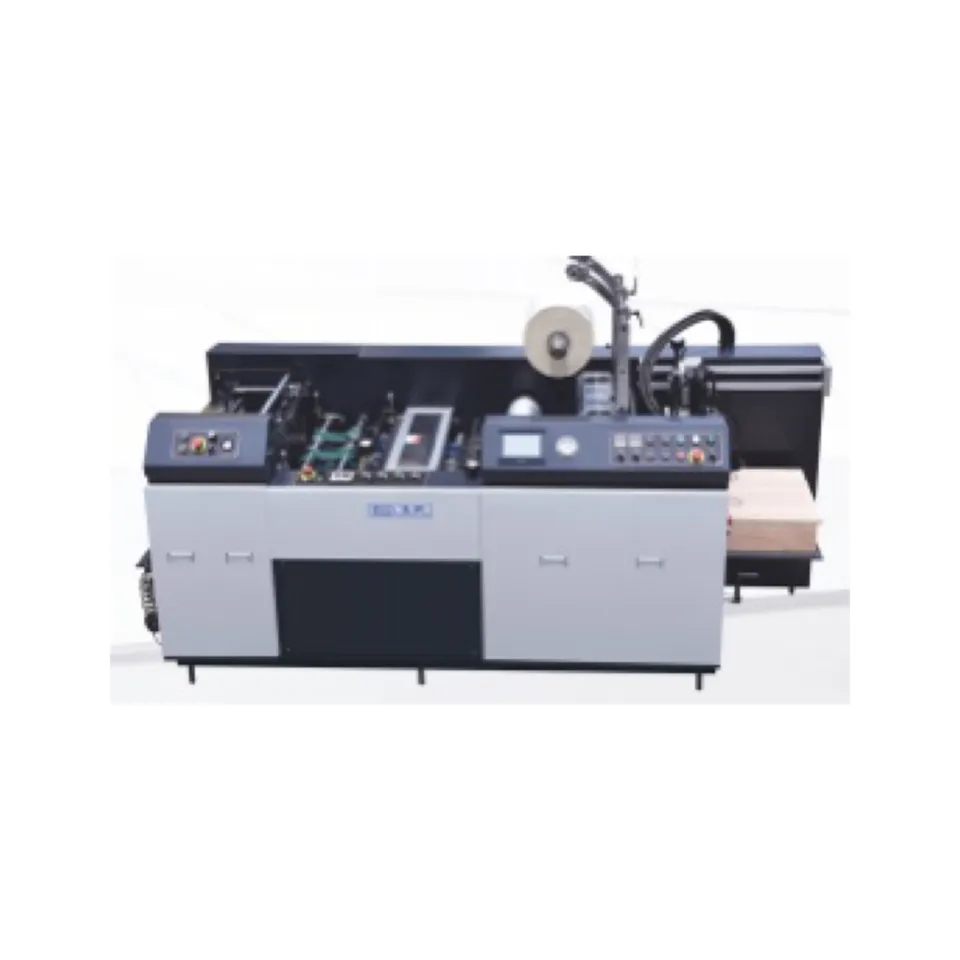

Automatic Embossing Laminating Machine

Best solutions for photo printing, protecting and decorating. Here we have a ideal model to suit your needs and budget. Find details about China automatic embossing laminating machines in NEW STAR company.

Model:YFMA-590Y/760Y

Send Inquiry PDF DownLoad

Automatic embossing laminating machine made in China can be bought with low price from NEW STAR, which is a professional high quality products manufacturers and factory in China. We provide customized products service. If you want quotation, you can ask us by leaving a message. We will get back to you as soon as possible.

Automatic embossing laminating machine

YFMA-590/760Y automatic embossing laminating machine has effectively solve the biggest pain point in the photo development industry: unable to meet the environmental protection requirements. Green environmental protection, help your enterprise develop green and sustainable! Innovative four roller embossing mechanism, multiple textures can be switched with one key to improve efficiency.

Product Parameter (Specification)

|

Item |

YFMA-590Y |

YFMA-760Y |

|

Max laminating paper |

590*760mm |

760*890mm |

|

Min laminating paper |

240*240mm |

240*240mm |

|

Paper weight |

100~450g/㎡ |

100~450g/㎡ |

|

Catch-up error |

+_2mm |

+_2mm |

|

Laminating speed |

0~80m/min |

0~80m/min |

|

Power |

20kw |

20kw |

|

Paper feed height |

780mm |

780mm |

|

Paper stack height |

650mm |

650mm |

|

Overall Dimensions |

6800*1300*1800 |

6800*1300*1800 |

|

Toatl weight |

6000kg |

6000kg |

Product Feature And Application

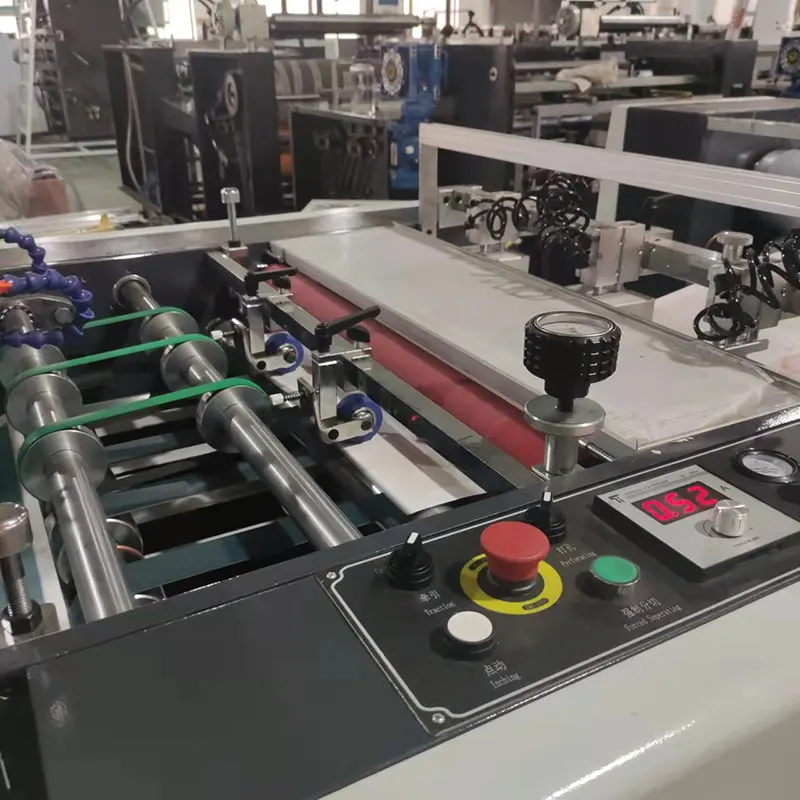

1.Automatic paper feeder adopts oil-free vacuum pump to feed paper automatically.

2.Automatic paper feeding system is equipped with no paper protector and paper break protector, which are controlled by photoelectric and mechanical systems. When no paper or paper break occurs, the machine will stop automatically for self-protection.

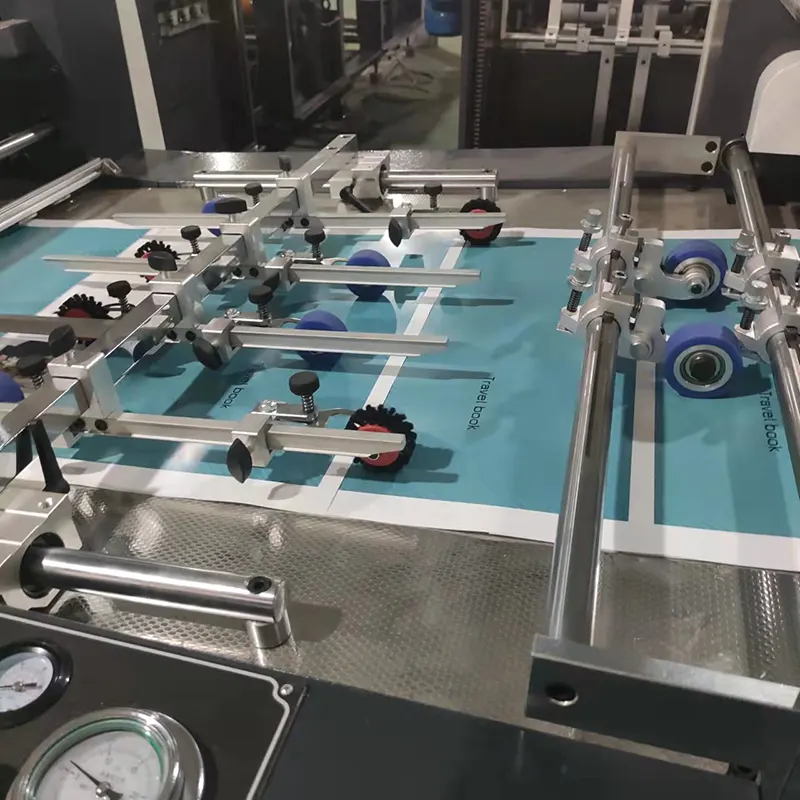

3.Conveying table is furnished with air aspirator and front lay etc. to guarantee paper conveying and overlap stable and regular.

4.High precision of chrome plated heating roller is equipped with oil circulation heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

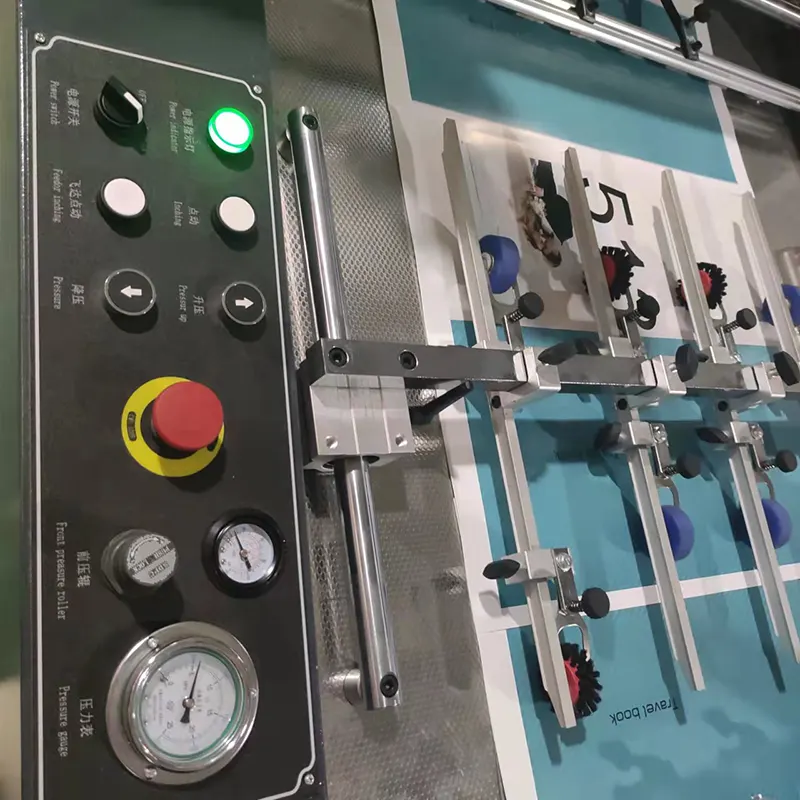

5.Pneumatic pressuring system provides automatically steady pressure to guarantee good laminating quality. The pressure is adjustable upon applications.

6.Air expansion shaft releases film, and precisionizes film release, and also makes the loading and unloading of film roll more convenient.

7.The combination of air expansion shaft and braking device can adjust film release tension and speed.

8.Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle.

9.Film perforating wheel perforates film edge for the automatic cut of laminated paper.

10.Anti-curvature device: when going through the anti-curvature device, the laminated paper shall be leveled at once and won't curve again after cut.

11.Pneumatic cutting system realizes automatic paper cut.

12.Auto paper collector equipped with pat device stacks and tidies up cut paper. Patting frequency of pat device is adjustable.

Product Details

|

Automatic paper feeding system. |

Laminating system |

Separation system |

|

1: big format feeder 2: sucking flat table( belt wide 10cm) 3: front guild 4: High accuracy servo overlap 5: Anti-clutter magnet safety device

|

1: electromagnetic heating 2: film straigt roller 3: automatic pressure 4: paper lacking and breaking system 5: double-sided lamination (optional) |

1: back perforating system 2: anti-curve system 3: pneumatic perforating cutting system 4: Magnetic particle clutch control |

|

|

|

|

|

|

|

|

|

Embossing System |

automatic paper stacker |

|

1: can choose silk and frosted patterns or customized patterns 2: Pre-heating makes the effect better 3: Cold forming, more 3D |

1: stacker 2: counter 3: Automatic lifting |

|

|

|

|

|

|