- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

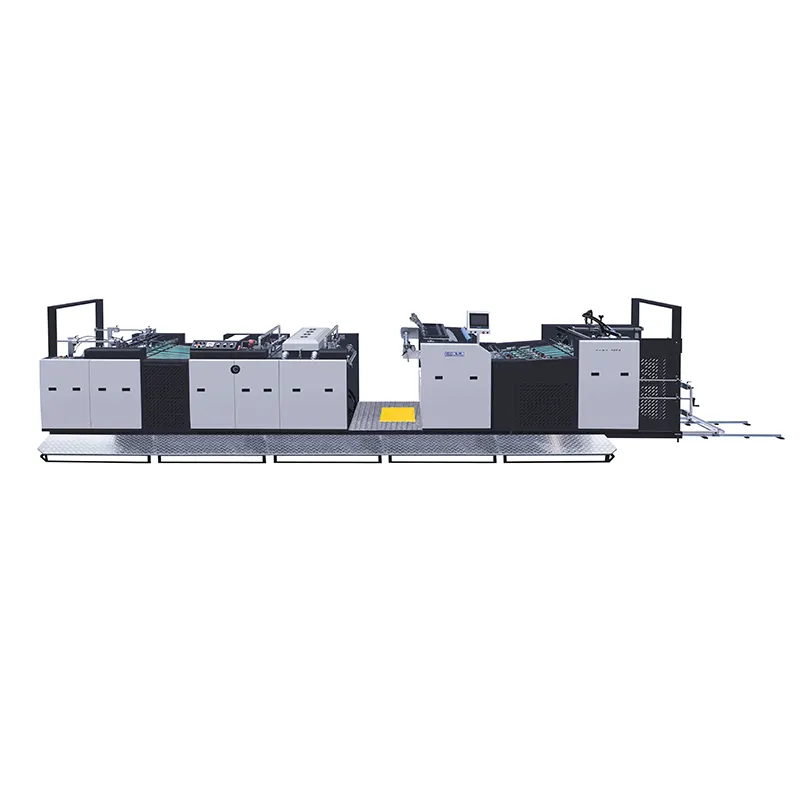

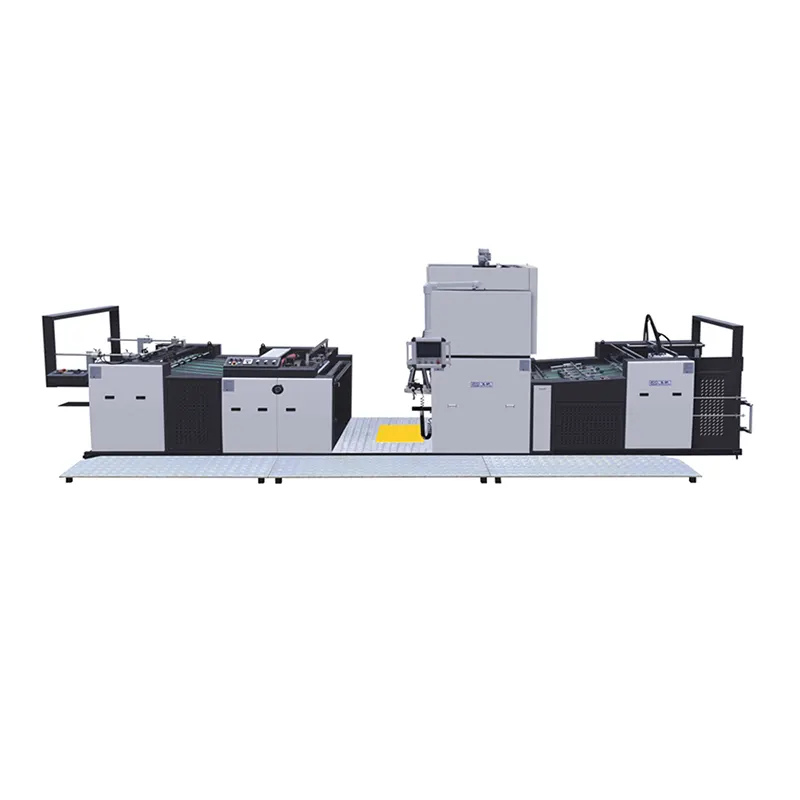

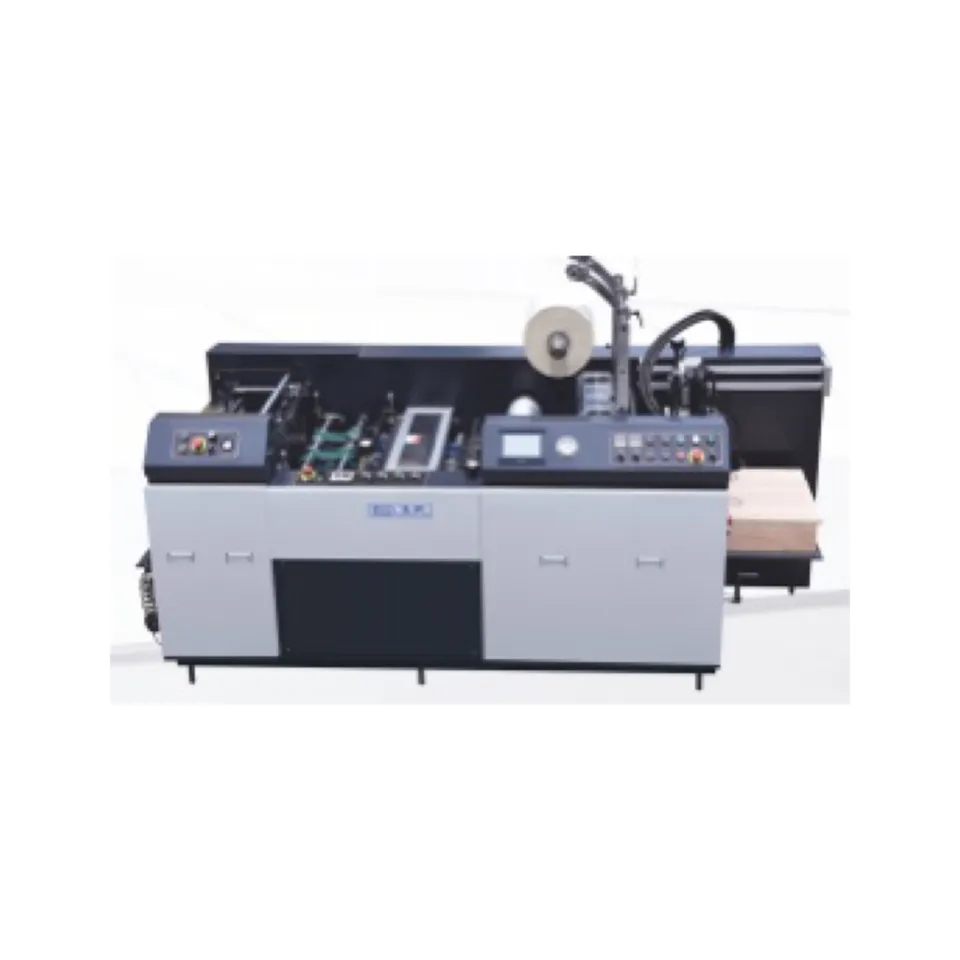

Automatic Pre coating Single Face Film Laminating Machine

Send Inquiry

Our factory specializes in manufacturing of Multifunctional Automatic laminating machine, NEW STAR was set up formally in2010, as one of the professional China Multifunctional Automatic laminating machine manufacturers and China Multifunctional Automatic laminating machine suppliers, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Multifunctional Automatic laminating machine and so on.

Automatic Pre coating Single Face Film Laminating Machine

YFMA-760 Automatic single face laminating machineis compact in structure and occupies less land. It is an ideal laminating equipment for printing plants and post press processing. It is suitable for business and digital laminating of various formats. You can make the most suitable choice according to the requirements of specific site and format.

Product Parameter (Specification)

|

Item

|

YFMA-590

|

YFMA-760

|

|

Max Laminating Paper

|

590*760mm

|

760*950mm

|

|

Max Laminating Paper

|

210*240mm

|

240*270mm

|

|

Paper weight

|

80-500g/㎡

|

80-500g/㎡

|

|

Overlap error

|

±2mm

|

±2mm

|

|

Laminating speed

|

one side: 0-80m/min

double side: 0-60m/min

|

one side: 0-80m/min

double side: 0-60m/min

|

|

Power

|

20kw

|

18kw

|

|

Paper feed height

|

680mm

|

780mm

|

|

Paper stack height

|

650mm

|

750mm

|

|

Overall dimensions

|

4000*1350*1650mm

|

5500*1500*1800mm

|

|

Total weight

|

4000kg

|

4500kg

|

Product Feature And Application

-

High-Speed Lamination: The machine has a high-speed capability of laminating up to 60 sheets per minute, making it ideal for high-volume lamination tasks.

-

Automatic Feeding System: The machine has an automatic feeding system that ensures smooth and consistent feeding of materials, reducing the chances of jams and misalignments.

-

Adjustable Temperature: The temperature of the laminating rollers can be adjusted to suit the thickness of the materials being laminated, ensuring optimal results.

-

A3 Size Accommodation: The machine can accommodate materials up to A3 size, making it suitable for a wide range of applications.

-

User-Friendly: The machine is designed to be user-friendly and easy to operate, with intuitive controls and a clear display.

-

Energy-Efficient: The machine is energy-efficient, helping to reduce operating costs and environmental impact.

-

Cost-Effective: The machine is cost-effective, offering a high level of performance and reliability at an affordable price.

Product Details

|

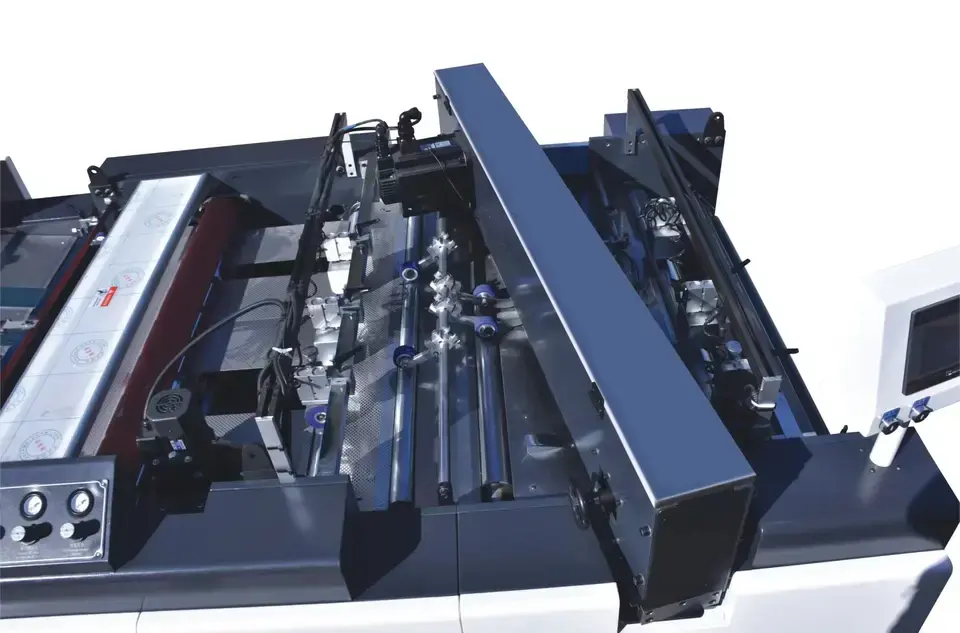

Automatic paper feeding system. |

Dust removal and front guild system |

Laminating system |

|

1: pre-loading feeder 2: non-stopped feeder 3: big format feeder 4: sucking flat table 5: front guild 6: Servo has high precision 7: Anti-clutter magnet safety device |

1: Mirror iron roller 2: Heating dust removal 3: Scraper cleaning powder 4: Synchronous belt drive |

1: electromagnetic heating 2: film straigt roller 3: temperature meteroutside 4: automatic pressure 5: paper lacking and breaking system 6: Double-sided lamination (optional)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

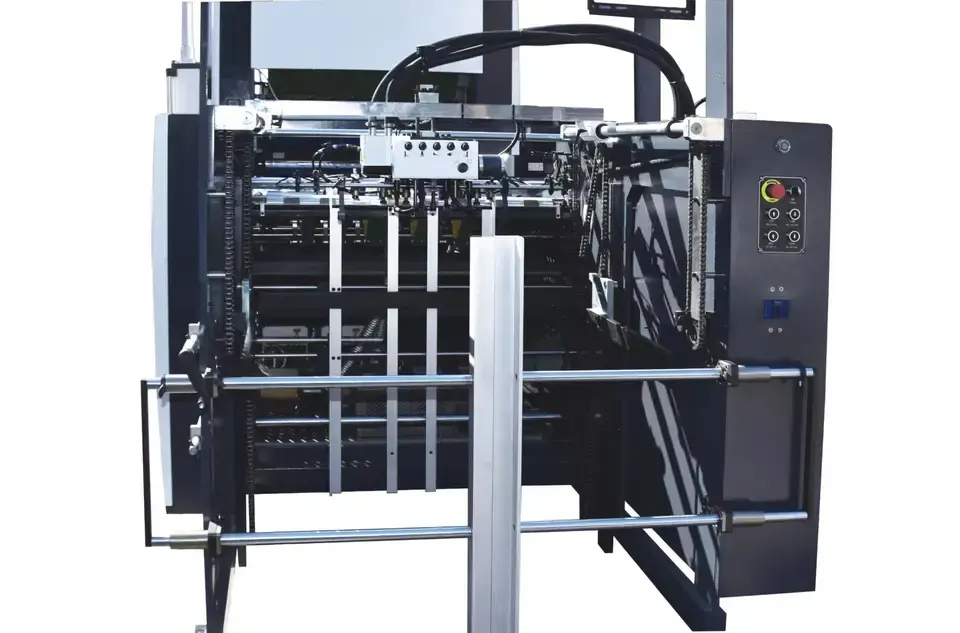

UV Dryer |

Separation system |

automatic paper stacker |

|

1: sucking and outside air system 2: The UV part adopts 8-12KW adjustable electronic light source, which greatly improves the safety performance compared with the traditional voltage source light source, and can adjust the brightness of the light source automatically according to the change of the running speed of the machine, which can be changed from 30% to 100%. The average energy consumption is saved by more than 30%. |

1: back perforating system 2: high speed rotation knife 3: anti-curvev system 4: pneumatic perforating cutting system 5: slot for the separating roller |

1: vacuum sucker flat ,belt width 10cm 2: non-stop feeding 3: 850mmtheheight of the paper load 4: counter 5: Paper flap device 6: The electric eye sensor automatically lowers, and the paper output wind pressure adjustment function 7: The intelligent automatic waste discharge system automatically discharges uncut products to avoid scrapping due to paper jams. |

|

|

|

|

|

|

|

|