- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

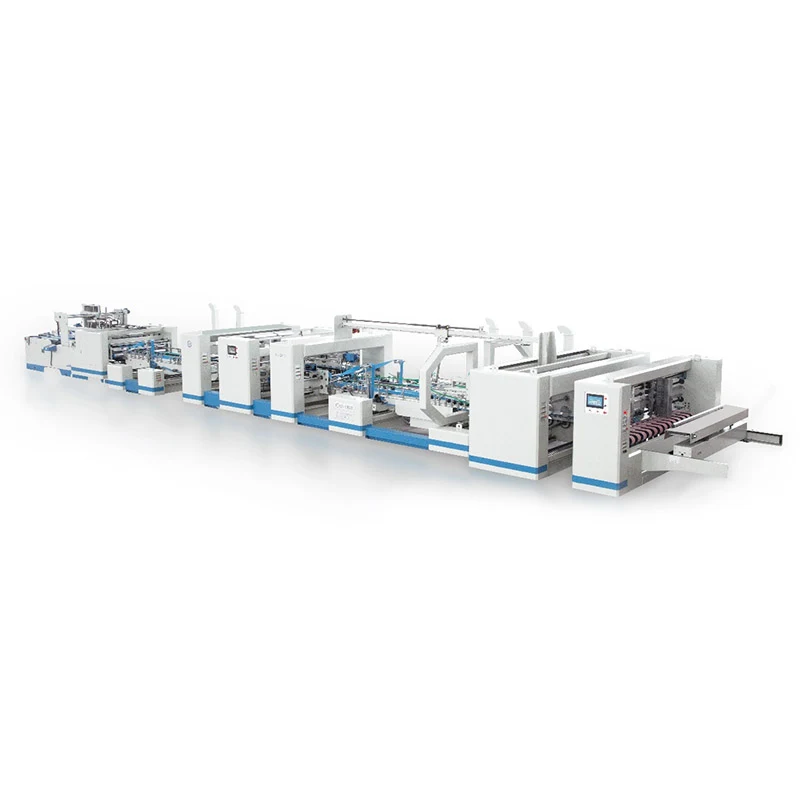

Automatic Folder Gluer Machine

NEW STAR provides customers with a variety of automatic folder gluer machines. China factory focus on designing high intelligent, high efficiency products to suit clents' requirements. Easy and simple to handle by green hand. Contact us for details if you need to purchase.

Model:XS-650/850

Send Inquiry PDF DownLoad

NEW STAR facoty specializes in the development and production of medium and high-end automatic folder gluer machine inChina, complete models and specifications, and a wide range of functions. The company can also according to the actual situation of customers demand for personalizedcustomized services.

Automatic folder gluer machine

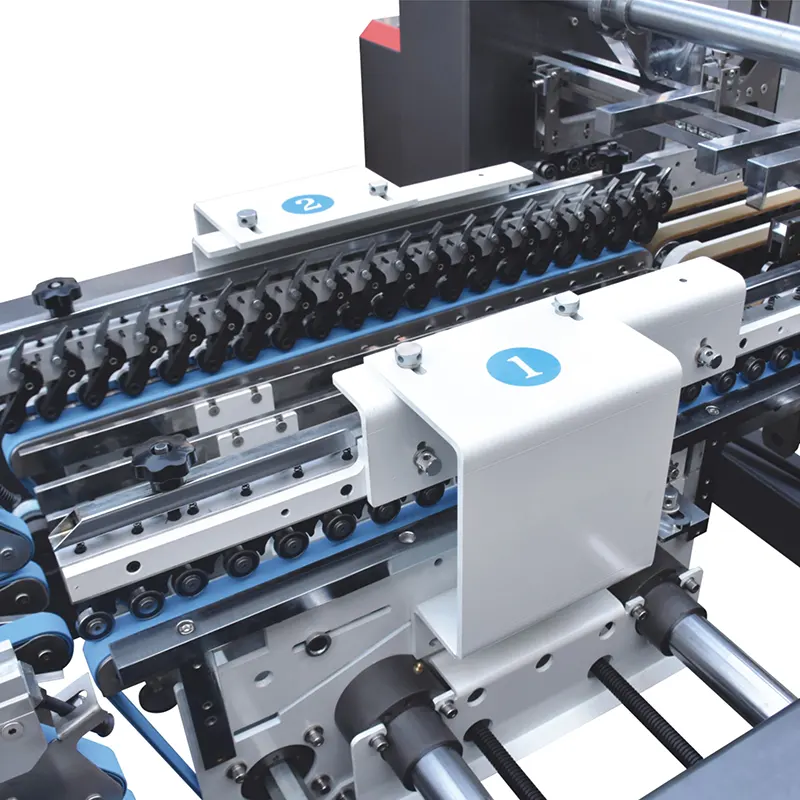

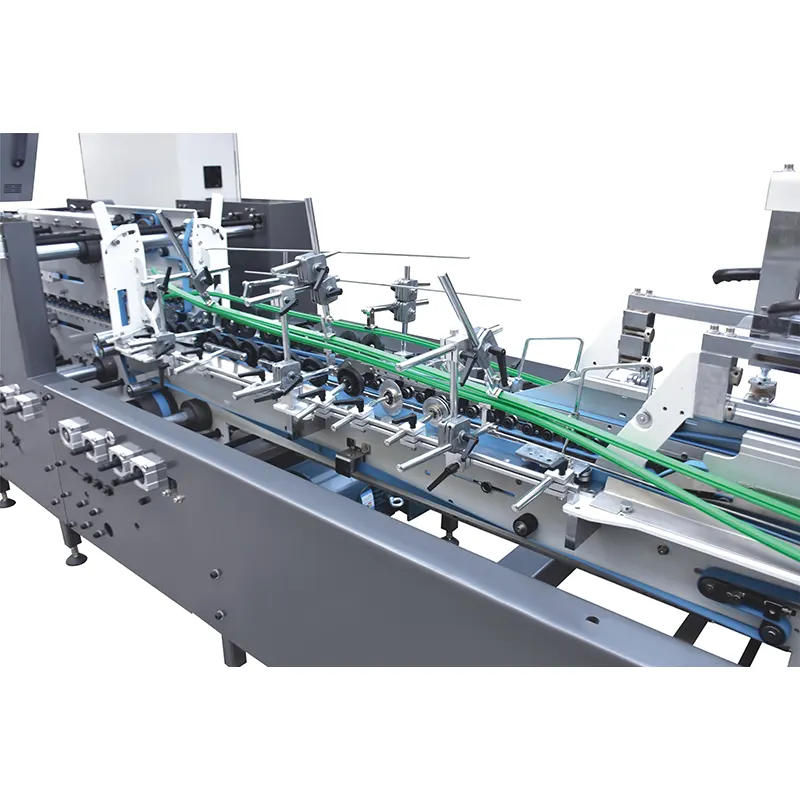

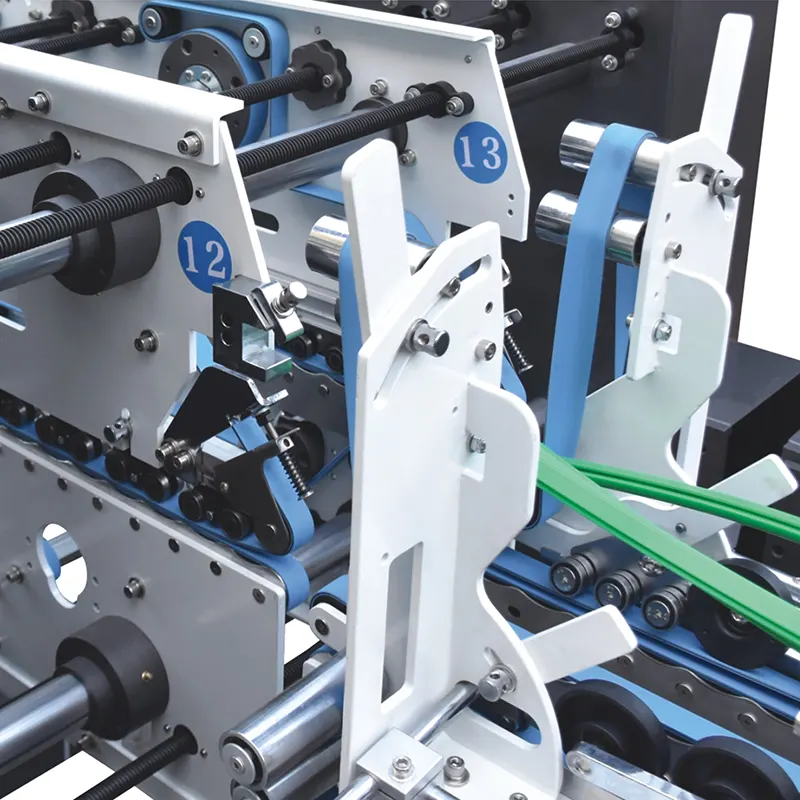

Automatic folder gluer machine: the output part is equipped with an electronic paper kicking counting module with a white belt tensioning device; The conveying section is driven by an independent motor.

The conveying speed can be adjusted automatically or manually according to the speed of the main machine in cooperation with photoelectricity.

Lock bottom: 3 sets of upper and lower guide plates and a complete set of front hook device to ensure smooth and accurate lock bottom action.

It adopts man-machine interface, PLC operating system, and is equipped with remote control system, which is easy to adjust and operate.

Product Parameter (Specification)

|

Model |

XS-650B |

XS-850B |

|

Max blank width |

650mm |

850mm |

|

Dimension(L) |

12500mm |

13000mm |

|

Dimension(W*H) |

1400mm*1600mm |

1600mm*1600mm |

|

Mechanical weight |

5.5T |

7T |

|

Mechanical power |

14.2kw |

19kw |

|

Suitable material |

200-800 gms cardboard and N、E、F&B flute corrugated board |

|

|

Speed range |

0-400 m/min |

|

|

Inching Speed |

30m/min |

|

|

Compressed air |

6bar |

|

|

Air compressor capacity |

10m3/h |

|

|

Air tank capacity |

60L |

|

Product Feature And Application

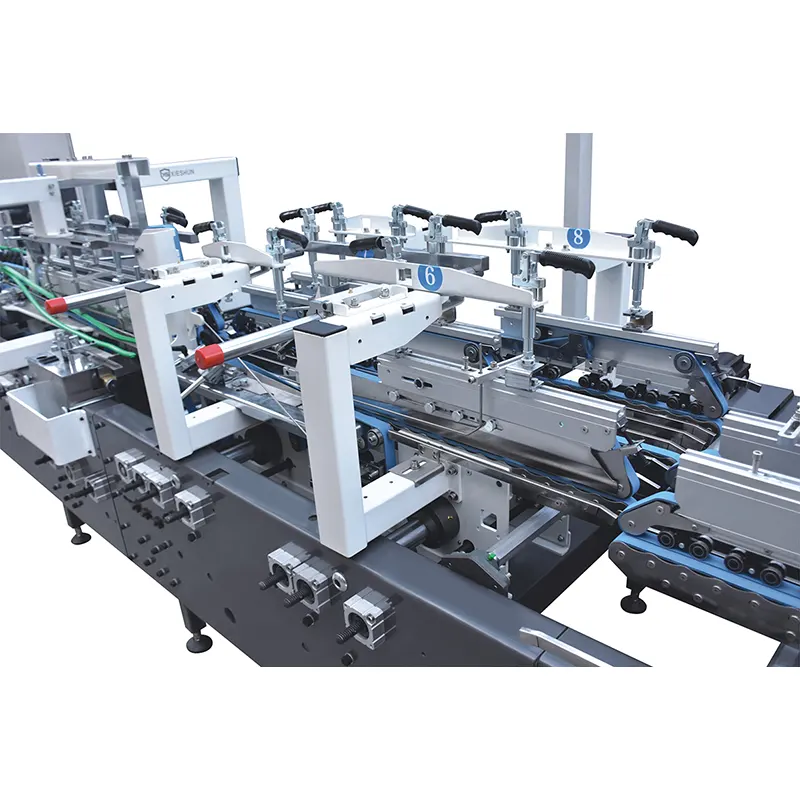

1. This machine adopts a color touch screen human-machine control system. The belts on both sides of the fold adopt servo motors to follow the lower belt to increase and decrease, synchronous tracking parameter setting system, and the transmission speed of the main machine and the press conveying section automatically increases and decreases. Synchronous tracking parameter setting system.

2. Each section of the machine is moved and adjusted by electric movement, which is simple and convenient, fast and efficient for single person to operate.

3. High-power stepless speed-regulating frequency conversion and high-efficiency powerful motor. The maximum speed can reach 400 m/min, and the power transmission adopts multi-ribbed belt, which has low noise, high efficiency, easy maintenance, and is in line with economic and high efficiency.

4. All functional components of this machine are modularized, which is convenient and quick to combine, and it saves time for changing the box-making products and debugging. Beginners are easy to master the technology, easy to understand and learn.

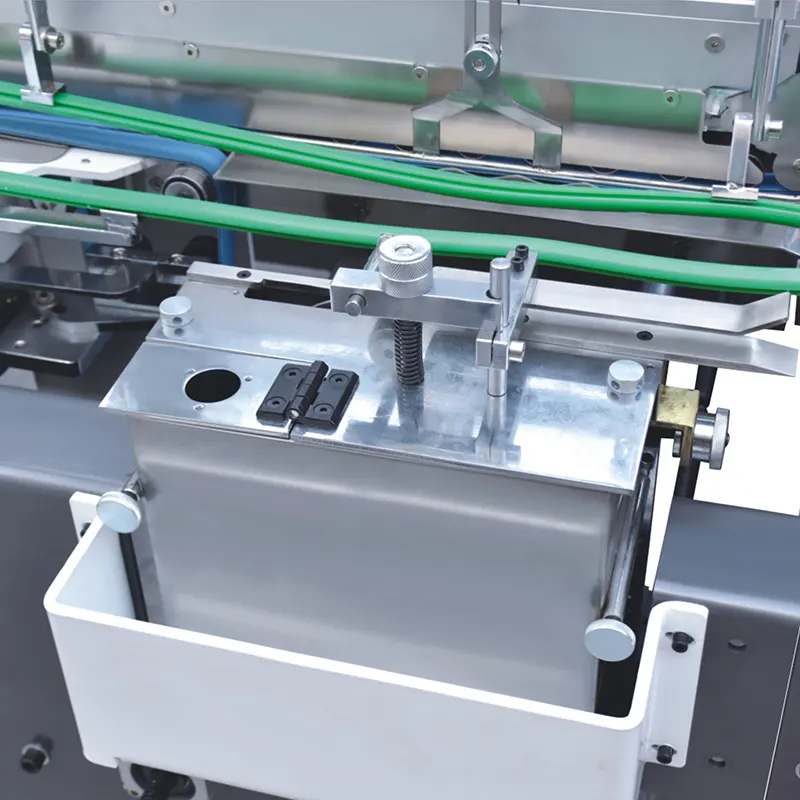

5. The left and right bottom glue cylinders and glue spraying system are matched with the unique design of the bottom locking product.

6. Using photoelectric counting, total or quantitative counting is possible, and it is equipped with kick board mark and water spray mark to distinguish the quantity.

Product Details

|

Feeder –Set up quickly and rapidly –Variable speed independent servo motor –Adjustable on the run –Easy repeatability –Light maintenance –Feeds most types of materials –Handles most box styles –Feeder Air suction(optional) |

Alignment –The paperboard sent by feeder shall be corrected by the alignment to ensue go straight. –The upper pressure drive can be adjusted up and down to adapt to different paperboard thickness. –Alignment is lengthened to 1400MM to ensure the correction effect of long boxes. |

|

|

|

|

Crash-lock module (Optional) –Processes multiple-fold packaging –Telescopic upper conveyors easily be adjustable to box format –Allows for front panel folding |

4 & 6-corner device (Optional) –Fast set-up of all types, and most sizes, of 4 and 6-cornered boxes –Speeds of up to 22,000 b/h –Tilting frame adjusts to flap size –Cable guides for 45°panel –Modulated hook trajectory for high-speed, high-quality production –Gluing guns are required for 4/6 corner boxes, minimum 3 guns are used for 6 corner boxes |

|

|

|

Lower gluing unit –Oversized stainless steel glue wheel for high-speed running –Unique scraper device with micro-metric adjustment for precise gluing –All components easily removable for quick cleaning –Gluing wheel is 10mm wide(Wheel thickness could be customized) |

Folding –3 plate structure with main drive –Choice of left, right or simultaneous folding –Automatic belt tensioning ensures quicker makeready –The left and right folding belt speed can be adjusted independently |

|

|

|

|

Transfer –Independent drive for complete control and faster job change –Synchronized kicker adjusts to carton arrival time –Adjustable transfer conveyors adapt to difficult box shapes –Height adjustable for a perfect box stream |

Delivery –Integrated box stream regulator for precise stream intervals and faster running –In manual mode, the belt moves at a constant speed and is not affected by the main motor speed. –Pneumatic pressure control is more accurate, to ensure bonding effect. |

|

|

|

Carton type

box size

|

Straight line box

|

|

|

Crashlock box

|

|

|

4 corner box

|

|

|

6-corner box

|

|

|

Double-wall box

|

|

Optional functions:

CD Box, Socks box, Flap align, Electric moving plate, 90°turning, Edge grinding, Power Edge grinding, Gluing guns, Plasma, Feeder Air suction, Pneumatic wharf, Delivery sponge belt.

Options:

| CD box | Socks box |

|

|

| 90°Turning | Grinder |

|

|