- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

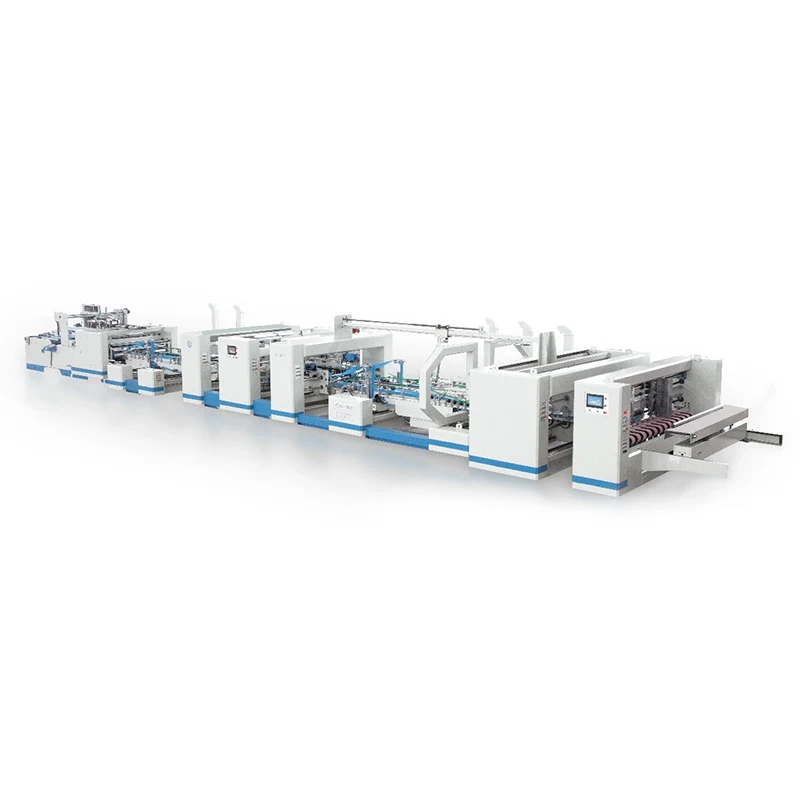

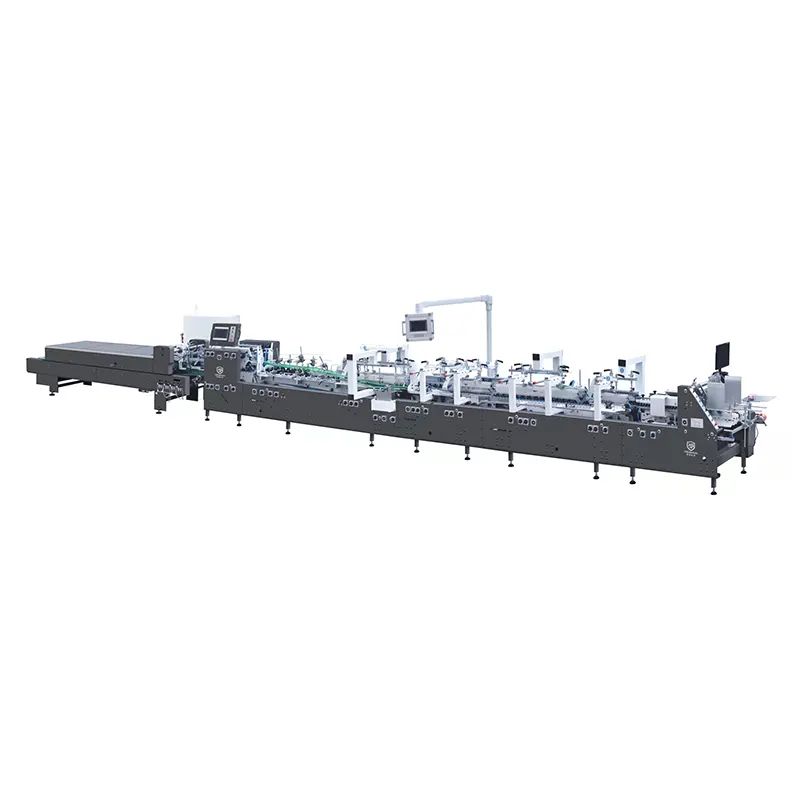

Corrugated Carton Folder Gluer Machine

Feihua is corrugated carton folder gluer machine manufacturer and supplier in China who can wholesale corrugated carton folder gluer machine.

Send Inquiry PDF DownLoad

High-Speed Automatic Corrugated Carton Folder Gluer & Stitching Machine (D-Series)

Product Paramete of Corrugated Carton Folder Gluer Machine

|

Model |

A (min) |

A (max) |

B (min) |

B (max) |

C (min) |

C (max) |

D (min) |

D (max) |

Power |

Net Weight |

Machine Size (LxWxH) |

|

GS-2400-D |

300 |

800 |

200 |

700 |

1100 |

2400 |

330 |

1200 |

40KW |

16T |

17x3.5x2.2 (m) |

|

GS-2800-D |

300 |

850 |

200 |

750 |

1100 |

2800 |

330 |

1200 |

42KW |

17T |

17x4.05x2.2 (m) |

|

GS-3200-D |

350 |

1050 |

180 |

850 |

1350 |

3200 |

330 |

1600 |

80KW |

23T |

27x4.8x2.3 (m) |

|

Feeding unit (the direction of the carton) |

Score Unit |

Folding Unit |

|

14 suction paper belts (100mm wide) for cardboard transfer. Adjustable belt distance via tension wheel for various cardboard widths. Power output through embossing wheel. Manually adjustable side baffles for different widths. 3 adjustable paper-out knives for varying cardboard thickness. Each belt can be moved left or right for precise positioning. |

Two adjustable guide plates (for different carton sizes). electric pressure adjustment based on thickness. four transmission flat belts inside the pressure roller for smooth and vertical transfer. Flat belts press the carton from top and bottom, ensuring vertical movement and preventing skewing. One pre-pressing wheel set and two pressing reel sets. Computer-controlled pressing wheels ensure precise adjustment Additional pressing on lines 2 and 4 for improved carton shaping |

Glue applicators adjust based on carton shape. Glue system includes rubberizing and pressing wheels. Motors adjust guide plates. Belts fold cardboard at 180 degrees. Guide wheels ensure smooth folding. Motors ensure smooth operation. Suction groove stabilizes belts. carton shaping is adjustable on independent motors. Pre-scored lines 2 and 4 are repressed after folding to ensure perfect square carton formation. flattening wheel preventing uneven height after molding. Spring steel sheet box setup saves time. |

|

|

|

|

|

Correction Unit |

Stacker |

Stitching Unit (Complete Import from Italy) |

|

Carton enters correction unit; adjustable belts reduce deviation. Guide plates adjust carton sealing size. Clapper and baffle ensure fast speed with low noise. Computer controls pressure box for efficient operation. Servo correction system provides additional adjustment. Touchscreen interface for fast and user-friendly operation. |

Automatic front and back cardboard placement. Fully automated, hands-free operation. Switchable delivery mode for small batches. Customizable discharge system to meet client needs. Simple adjustments for various cardboard types (A, B, E, three-layer, five-layer). Stacking height up to 1650mm for maximum efficiency. |

Correction block installed at stitching-correction junction, integrated with servo correction. Italian high-speed swinging stitching head, fiber optic-driven with computer-controlled servo. Stitching speed exceeds 1000 nails/min for continuous high-speed stitching. Stitching head lifts for gluing mode; fixed-speed carton conveyance. Stitching unit synchronized with host machine. Cartons fed by two 80mm wide belts with adjustable pressure for thickness. |

|

|

|

|

Notes

For more information, check with the download page to find the PDF document for this machine. There has more related information you can get from the document.