- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

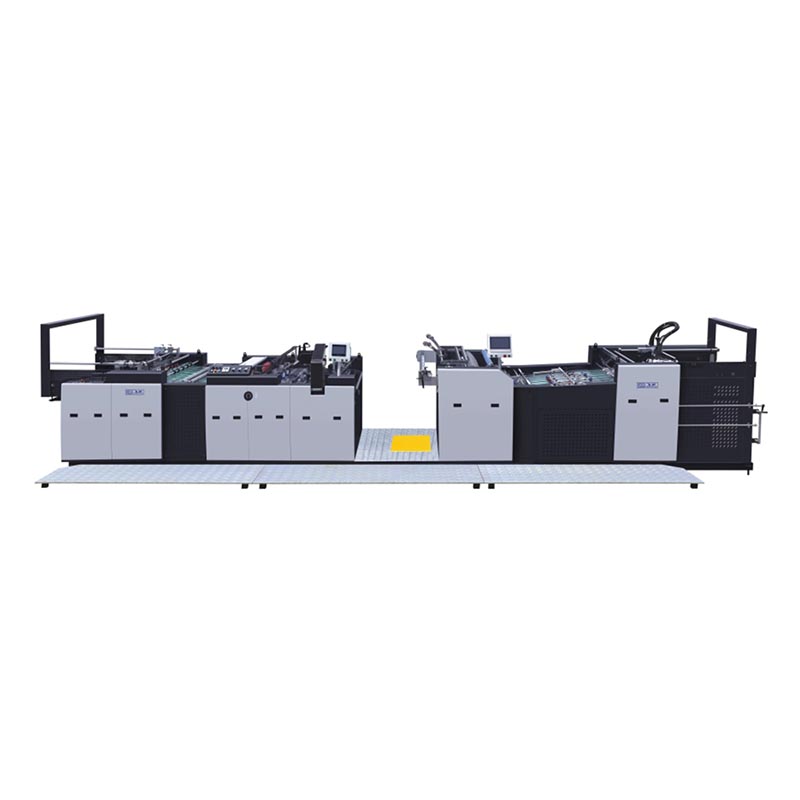

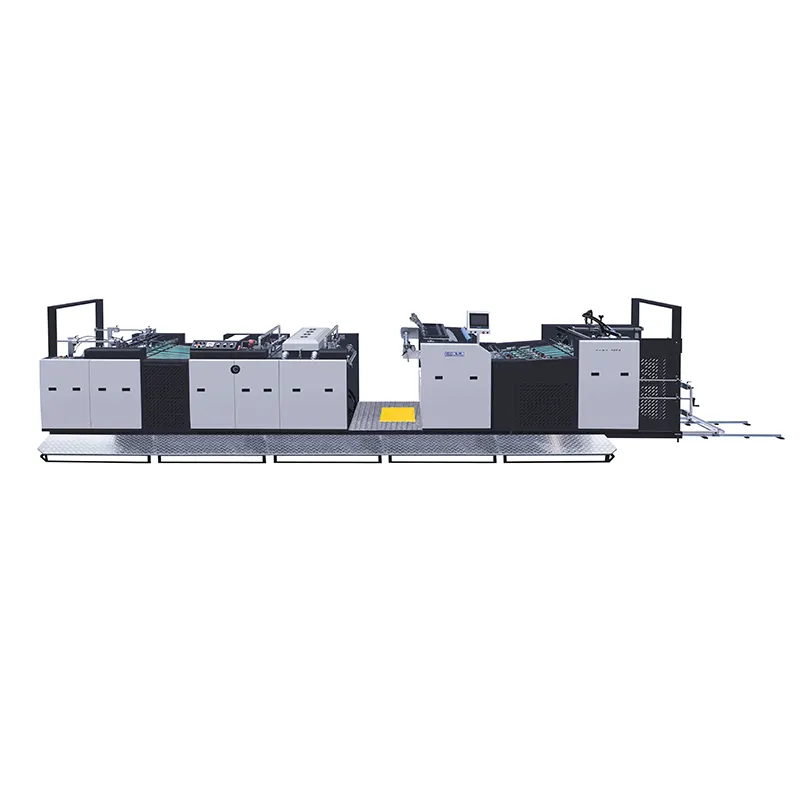

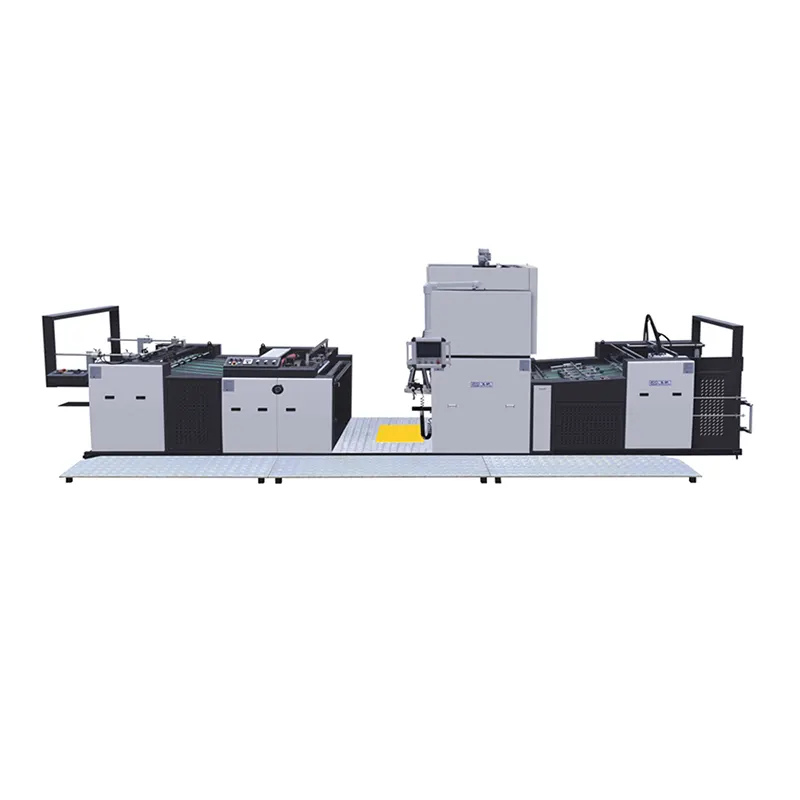

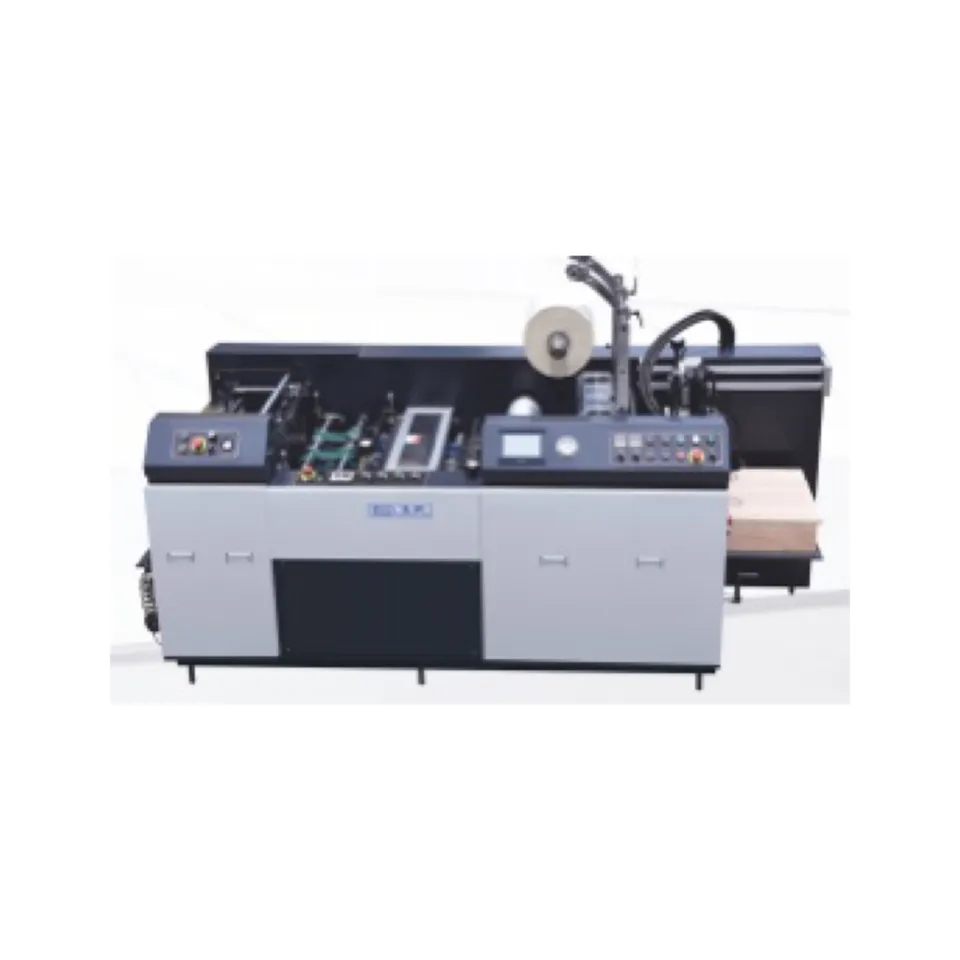

Automatic Laminating Machine With Chain Knife

Automatic laminating machine with chain knife adopts chain knife cutting technology , which has high speed, accurate cutting and no tail film. The excellent performance of this type of equipment can meet the needs of users for efficient production and solve various difficult film laminating problems. It is the ideal choice for customers. NEW STAR looks forward to your consultation at any time.

Send Inquiry

Product description

Wenzhou Feihua Printing Machinery Co., Ltd. is a much professional manufacturer of automatic laminating machine with chain knife for paper products. Since its establishment, it has been committed to the transformation and innovation of single-sheet printing surface processing equipment, striving to produce automatic equipment with stable quality, high efficiency, energy saving and easy operation; Our objective is to create higher value for customers and make NEW STAR's users more competitive in the market.

Automatic laminating machine with chain knife

Product Introduction

YFMA - L series high speed automatic laminating machine with chain knife adds chain knife function to the original pre-coated laminating machine. It is to hang the blade on the chain, and accurately cut the paper edge connected by the film at high speed through computer motion control calculation. It belongs to physical cutting, which is environmentally friendly, pollution-free and odorless. Especially suitable for the slitting of PET, PVC and aluminized film.

Product Parameter (Specification)

|

Max laminating paper |

mm |

760*1020mm |

|

Min laminating paper |

mm |

240*240mm |

|

Paper weight |

g/㎡ |

100~500 |

|

Catch-up error |

mm |

+_2mm |

|

Laminating speed |

m/min |

chain knife:0~60m/min |

|

Power |

kw |

25kw |

|

Paper feed height |

mm |

780mm |

|

Paper stack height |

mm |

750mm |

|

Overall Dimensions |

mm |

5500*1500*1800mm |

|

Toatl weight |

kg |

5000kg |

Product Feature And Application

1:Any combination of powerful multi-functional configuration can solve various problems of laminating process!

(1) Double-sided laminating (both sides are laminated at the same time)

(2) Dust removal (remove surface dust and surface preheating, enhance surface brightness/mattity/and fit)

(3) Chain knife (cutting of tailless film and high toughness film such as PET and aluminum foil film)

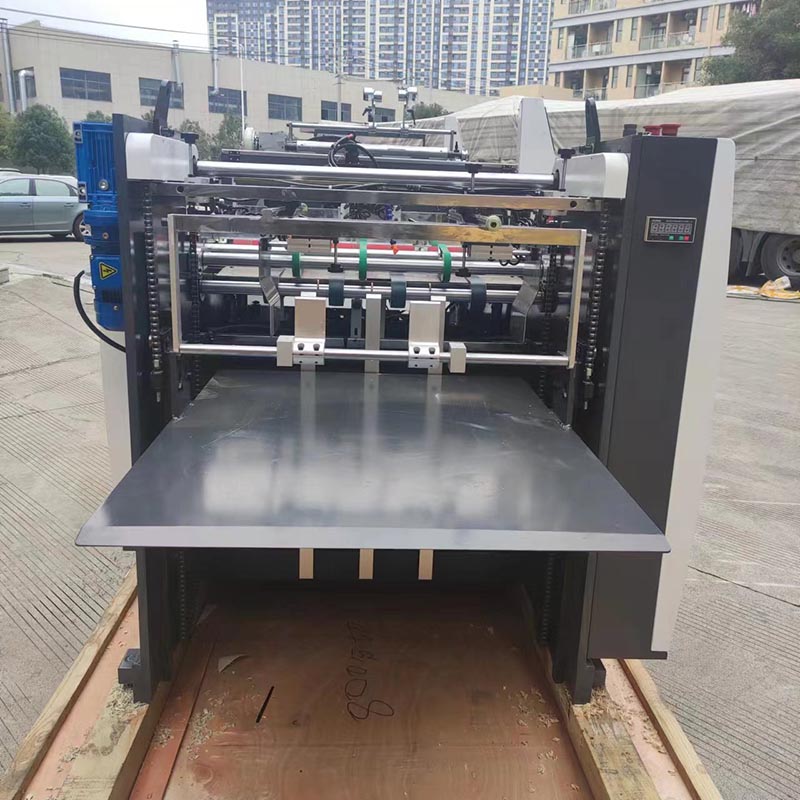

(4) Heavy Feeder head which can realize smooth paper feeding of thick cardboard.

(5) The gap of the pressure mechanism can be adjusted to realize the pressing of different thickness of paper.

(6) Embossing system: various embossing reflects the aesthetics of surface decoration!

2:Pre-stacker mechanism to realize non-stop paper feeding and receiving

3:Adopt high-speed heavy feeder (12000 sheets/hour) to ensure fast and stable operation

4:High degree of intelligence, the whole machine is controlled by PLC and man-machine, and each part is frequency-converted and servo-linked to ensure speed synchronization and easy for one person to operate.

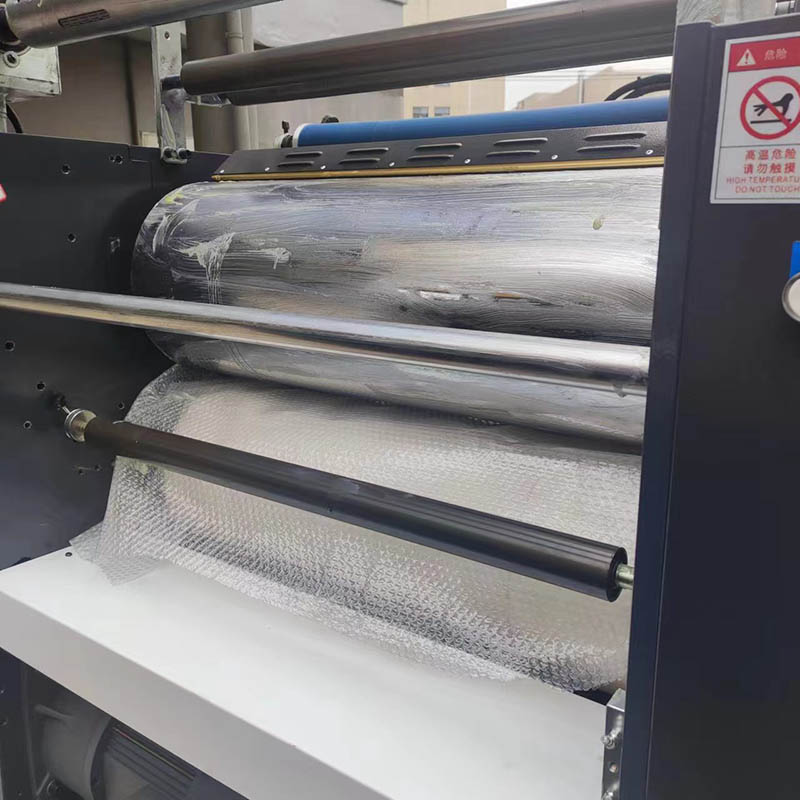

5:Electromagnetic heating system: the temperature rises and falls quickly, the heating roller adopts an electromagnetic heating system and a built-in oil heating system to make sure the temperature is uniform.

6:Driven by the synchronous belt, the equipment is more stable and the accuracy is better.

7:The equipment adopts servo overlaping, which has higher accuracy and more stability

8:The main pressure shaft is combined with electric pressure

9:Automatic lifting film, reducing labor intensity and safety

10:The main roller adopts double chain, no jump, high running stability, it is not easy to stretch after a long time, which affects the accuracy!

11:Feeder is driven by high precision independent servo motor.

Product Details

|

Automatic paper feeding system. |

Dust removal and front guild system |

Laminating system |

|

1:pre-loading feeder 2:non-stopped feeder 3:big format heavy feeder 4:sucking flat table 5:front guild 6: Servo has high precision 7: Anti-clutter magnet safety device |

1: Mirror iron roller 2: Heating dust removal 3: Scraper cleaning powder 4: Synchronous belt drive |

1:electromagnetic heating 2:film straigt roller 3:temperature meteroutside 4:automatic pressure 5:paper lacking and breaking system 6:Double-sided lamination(optional)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Separation system |

automatic paper stacker |

|

1:back perforating system 2:high speed rotation knife 3:anti-curve system 4:chain knife(optional) 5:pneumatic perforating cutting system 6:slot for the separating roller

|

1:vacuum sucker flat ,belt width 10cm 2:non-stop feeding 3:paper stacking height 850mm 4:counter 5: Paper flap device 6: The electric eye sensor automatically lowers, and the paper output wind pressure adjustment function 7: The intelligent automatic waste discharge system automatically discharges uncut products to avoid scrapping due to paper jams. |

|

|

|

|

|

|

|

|

|