- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

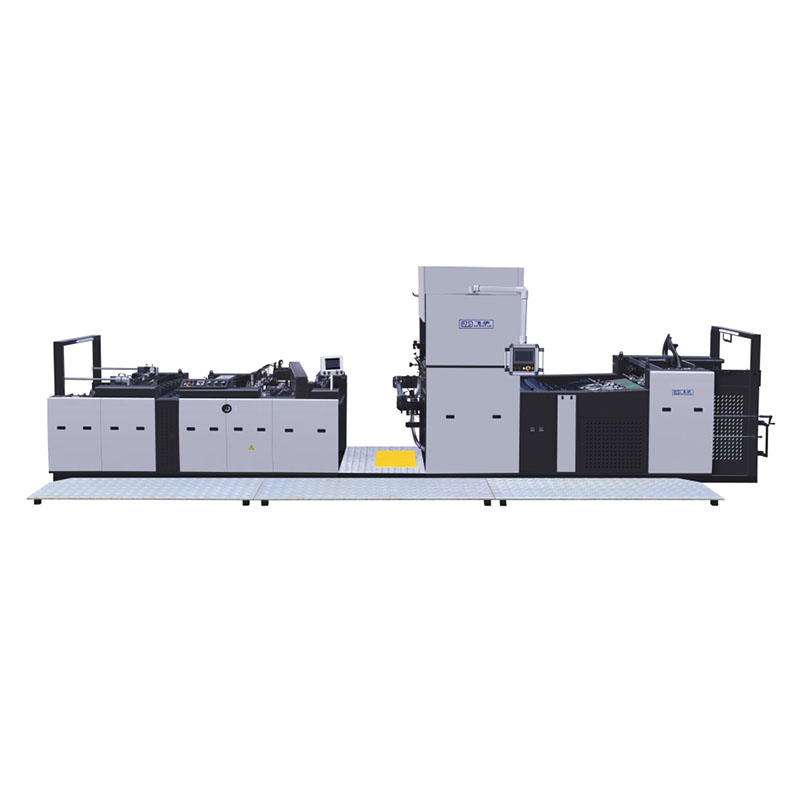

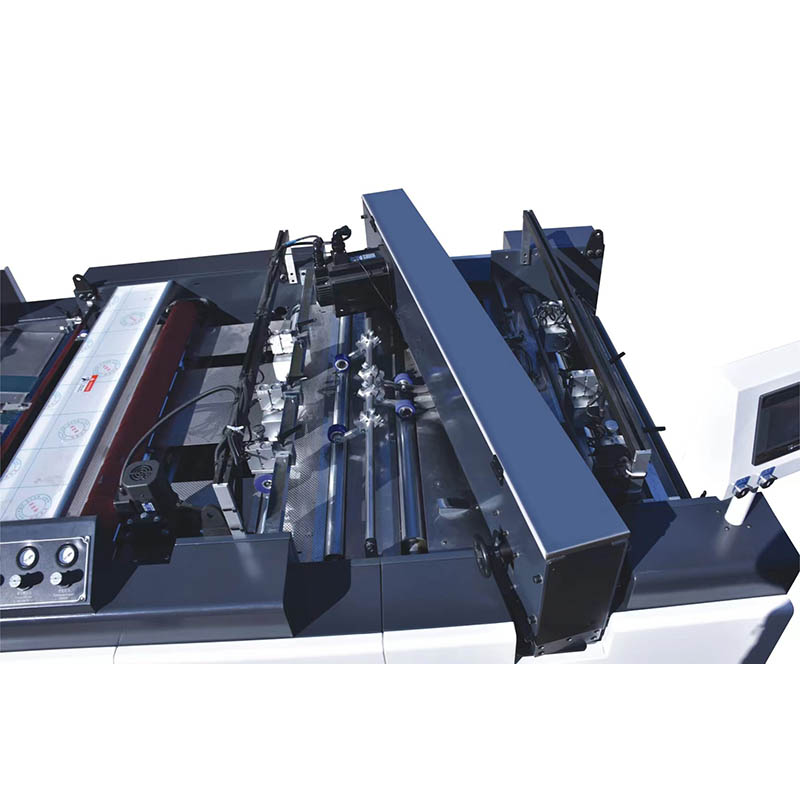

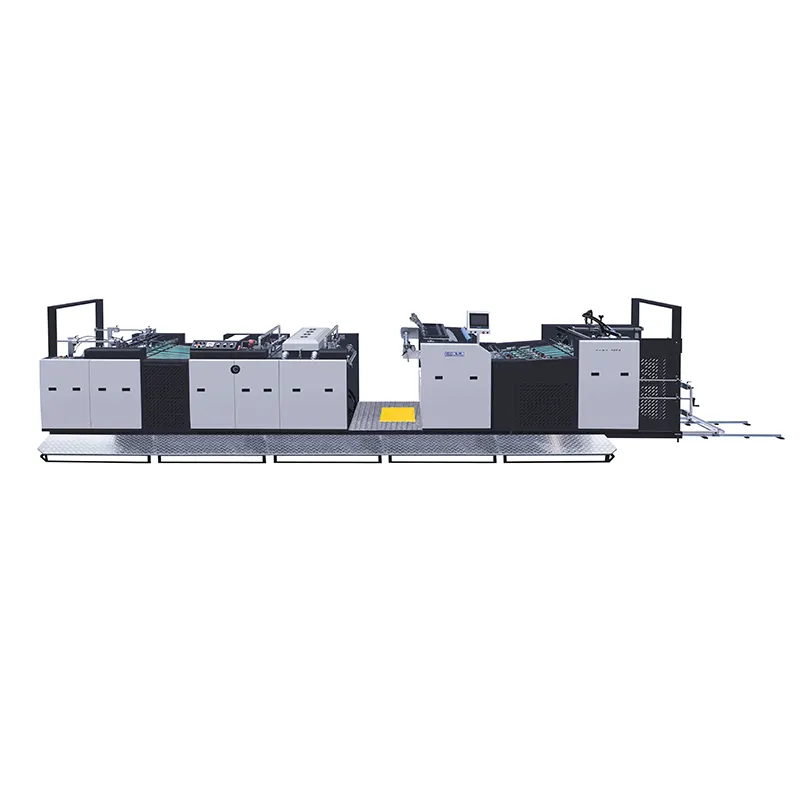

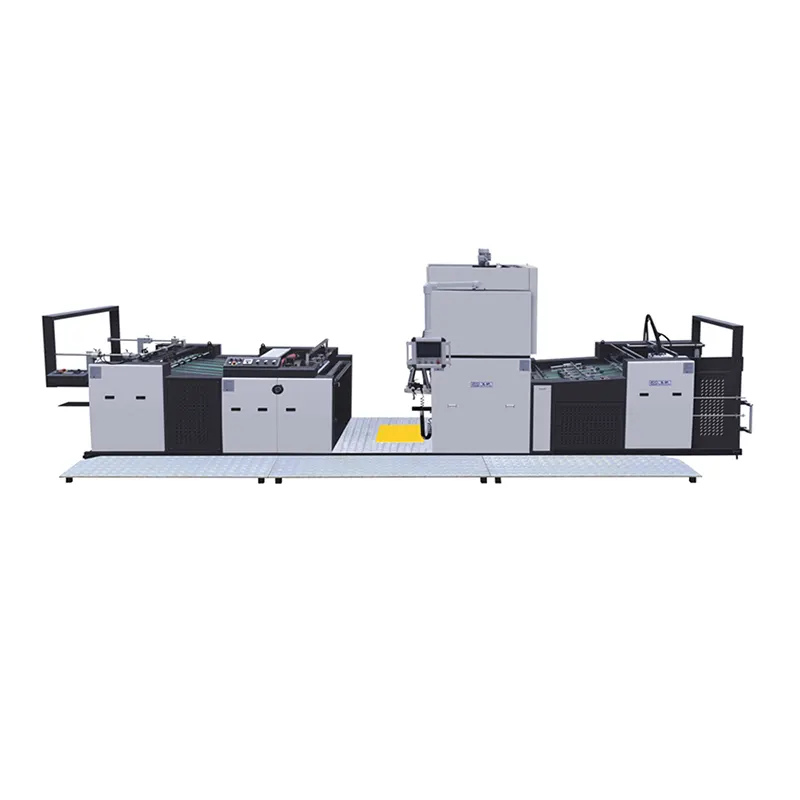

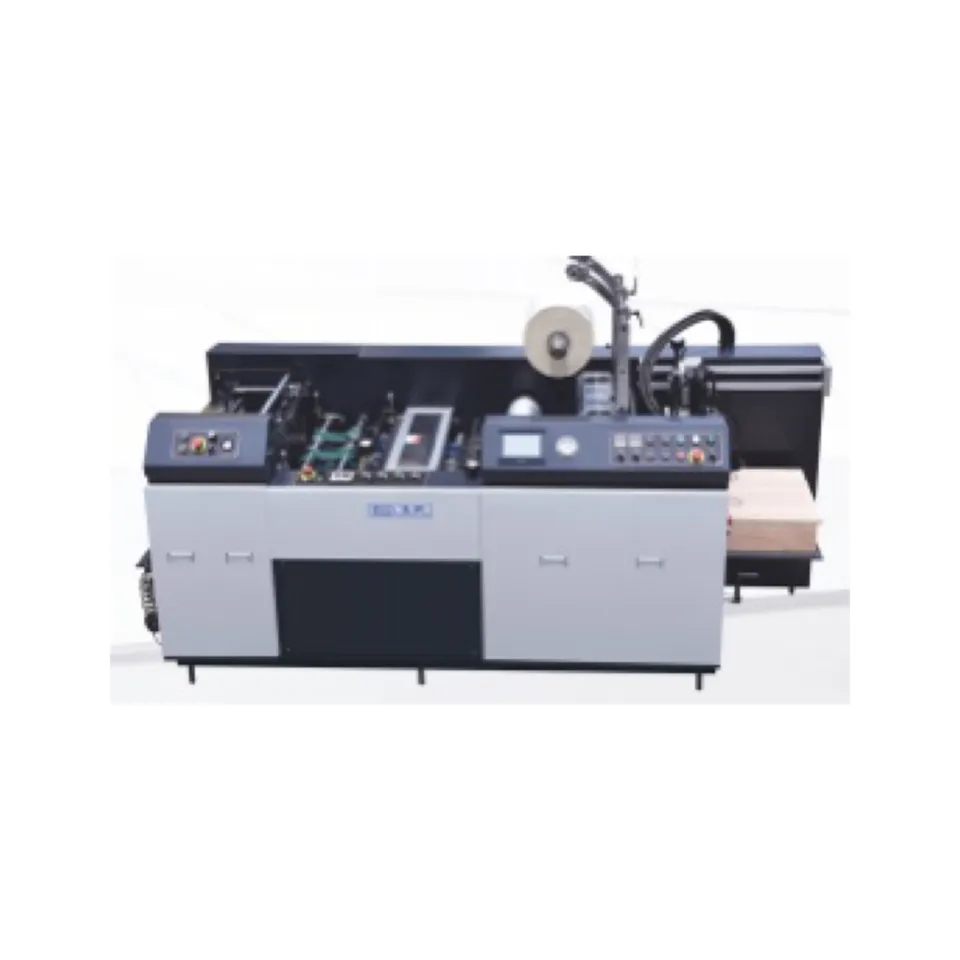

Automatic Vertical Laminating Machine With Chain Knife

Are you looking for a reliable, efficient and cost-effective way to laminate your vertical windows? NEW STAR Automatic Vertical laminating machine with Chain knife is an excellent choice for any business in need of high-quality lamination services. It’s reliable, affordable and provides perfect results every time!

Send Inquiry

Automatic Vertical laminating machine with Chain knife is specially designed for thin paper PET and PVC film slitting, and can be widely used in the lamination processing of books, color boxes, handbags and other products. It is an ideal equipment for post-press lamination with high quality and low price.

Automatic Vertical laminating machine with Chain knife Product Introduction

Automatic Vertical laminating machine with Chain knife is a high-speed energy-saving laminating machine newly launched by our company. It is a water-based and pre-coating dual-purpose machine. The whole machine adopts PLC control, temperature module, frequency converter, servo drive, synchronously running the speed of each unit; advanced 10-inch color screen man-machine interface, centralized program control, easy operation by one person; independent electrical box, safe control, maintenance convenient.

Among them, the chain knife machine adopts the original German ultrasonic probe system, German chain, and the large chain knife cuts quickly and accurately.

Product Parameter (Specification)

|

Item |

Unit |

FHS-850 |

FHS-1050 |

|

Max laminating paper |

mm |

780*1050mm |

|

|

Min laminating paper |

mm |

270*240mm |

300*300mm |

|

Paper weight |

g/㎡ |

80-500g/㎡ |

80-500g/㎡ |

|

Overlap error |

mm |

±2mm |

±2mm |

|

Laminating speed |

m/min |

oneside: 0~110m/min |

oneside: 0~110m/min |

|

Power |

kw |

60kw(different configuration, different power) |

65kw(different configuration, different power) |

|

Working power |

KW/H |

25KW |

28KW |

|

Paper feed height |

mm |

1150 |

1150 |

|

Paper stack height (with tray height) |

mm |

1050 |

1050 |

|

Overall Dimensions |

mm |

8600*1800*2000mm |

8600*2000*2000mm |

|

Toatl weight |

kg |

7500kg |

8000kg |

Product Feature And Application

1:Pre-stacker mechanism to realize non-stop paper feeding and receiving.

2:Adopt high-speed offset feeder (12000 sheets/hour) to ensure fast and stable operation

3:High degree of intelligence, the whole machine is controlled by PLC and man-machine, and each part is frequency-converted and servo-linked to ensure speed synchronization and easy for one person to operate.

4: The drying system adopts a hot air circulation system, combined with an active follow-up drying heating device, to improve the drying efficiency of acceleration and deceleration.

5:The main transmission of the whole machine adopts synchronous belt transmission, which makes the transmission stable and accurate, while ensuring the accuracy, greatly improving the stability and service life of the machine.

6:Electromagnetic heating system: the temperature rises and falls quickly, the heating roller adopts an electromagnetic heating system and a built-in oil heating system to make sure the temperature is uniform.

7:Any combination of powerful multi-functional configuration can solve various problems of laminating process!

(1)Powder removal: Remove surface dust and impurities to make the surface more beautiful and compacted!

(2)UV curing: Enhance the fastness of the film, especially to solve the problem of the film not sticking to the subsequent creasing and embossing!

(3)Double-sided: The upper and lower sides are laminated at the same time, with high efficiency and no waste!

(4)Double press: Good surface compaction, no whitening, stronger fit, double surface compaction and fastness enhancement effect!

(5)Embossing: Various embossing embodies the aesthetics of surface decoration!

(6)Chain knife: Slitting of tailless film and high toughness film such as PET and aluminum foil film!

(7)Hot knife: High-speed, tailless, for PET, aluminum foil film and other high-toughness film slitting!

(8)Corona: Solve the post-processing problems such as low corona value, screen printing, box pasting, stamping, etc.

(9)Injekt coding: Online Coding.

Product Details

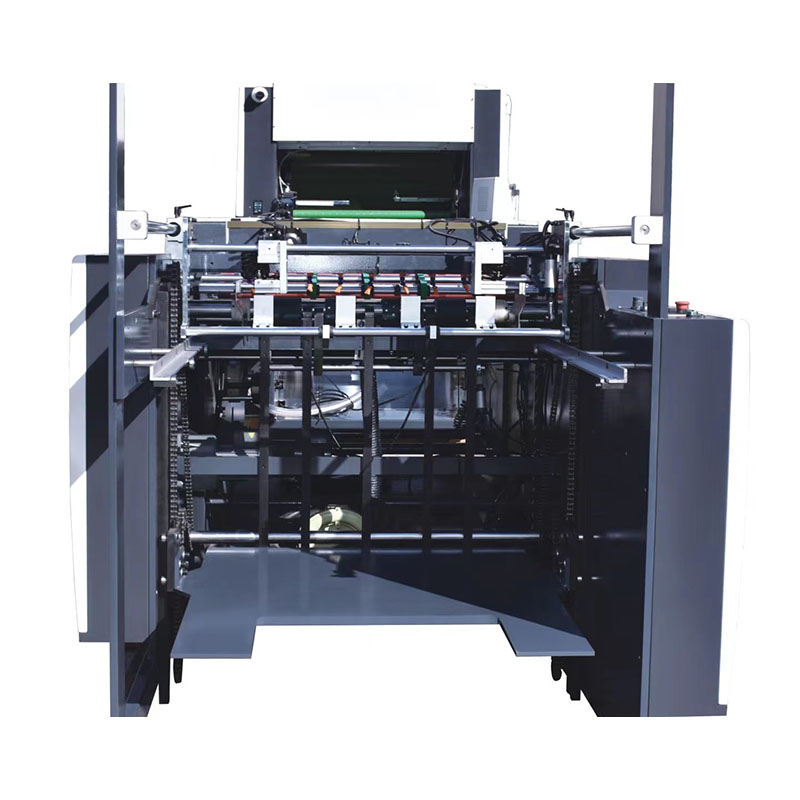

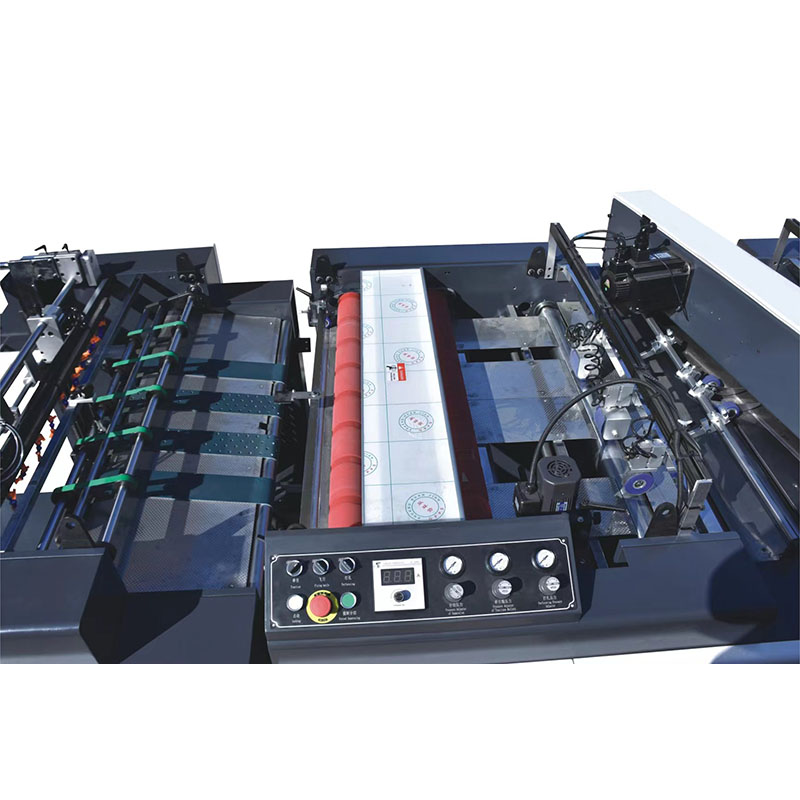

1. Automatic paper feeding system.

The paper feeder is an important part of the laminating machine. The function of the paper feeder is to separate the paper one by one automatically, accurately, steadily and periodically, and continuously send it to the regular positioning position.

The paper feeding method of this machine is continuous paper feeding, which has the advantages of high degree of automation, compact structure, good performance, convenient operation, accurate paper feeding and high precision. The main components of the paper feeder include the paper feeding bridge, the paper feeding head, the stacking table, the lifting system and the transmission system.

Adopt oil-free vacuum pump air suction system;

Adopt high-speed offset feeder (12000 sheets/hour) to ensure fast and stable operation;

Stepless frequency conversion speed regulation paper feeding;

The paper conveying table of the production line is positioned and conveyed by vacuum suction to ensure smooth, neat and stable conveying;

The paper feeding table is equipped with upper and lower limit protection devices; manual rapid lifting;

The paper feeding table has an automatic replenishment paper feeding system;

With double-sheet controller, double-sheet or multi-sheet feeding detection stop system, using the sensor of safety voltage detector;

Servo technology, PLC control and human-computer interaction system centralized control. Paper stacking error±2mm;

Front gauge and side lay positioning system.

Anti-debris magnet safety device, protect the iron roller.

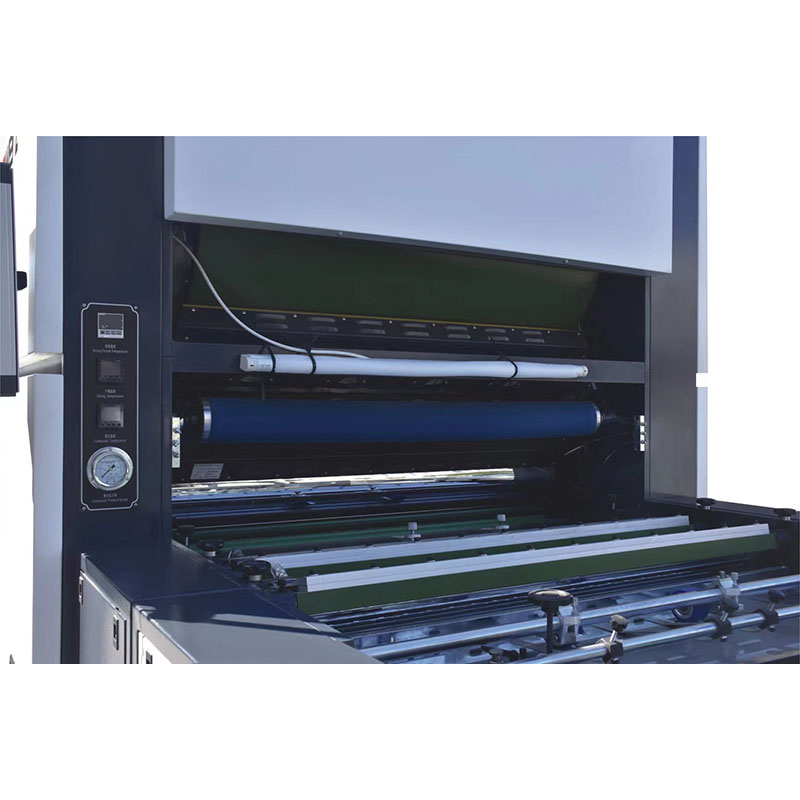

Main host

The whole machine adopts high-precision synchronous belt and some imported chain transmission;

380mm composite heating roller, matched with electromagnetic variable power heating system;

320mm imported silicone pressure roller, which has good temperature and pressure resistance and non-stick performance;

800mm large drying hot roller, coated with industrial non-stick material Teflon;

The drying system adopts a hot air circulation energy-saving system, combined with an active follow-up drying and heating device;

Computer monitoring system, safe and easy to operate!

Separation system

Back perforating system

High speed rotation knife

Anti-curve system

Pneumatic perforating cutting system

Slot for the separating roller

Adopt the centralized control system of the whole machine to realize precise pneumatic breaking

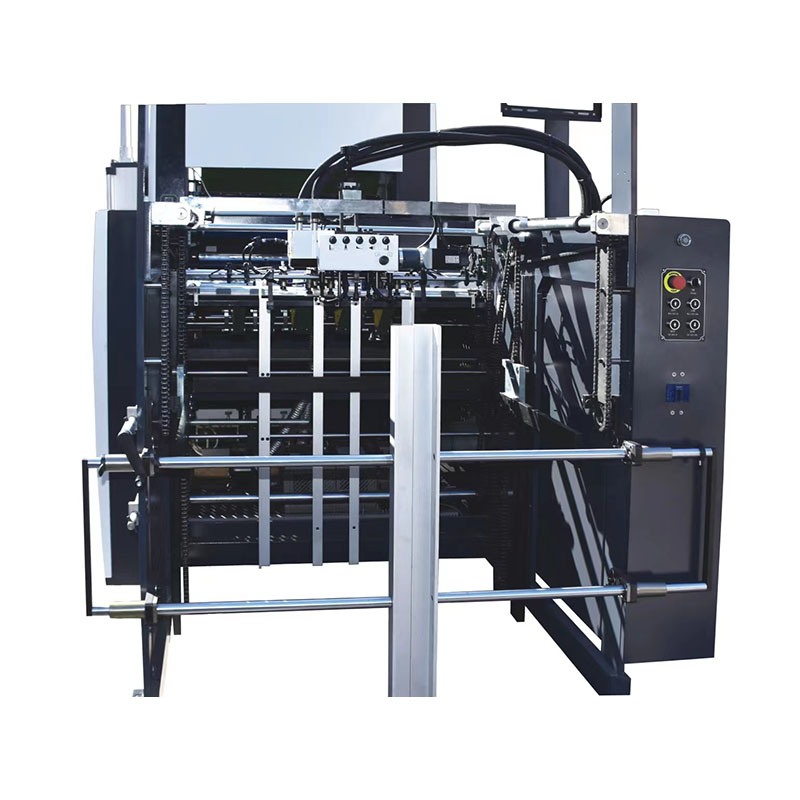

Automatic paper stacker

Thin paper corrugated paper delivery system, vacuum suction paper stabilizer device to keep the paper stable;

Manual fast lifting of the receiving table

The upper and lower limit protection devices of the receiving table;

The automatic lowering device of the delivery table, and the paper stop and alarm system at the limit of the delivery;

Automatic paper cumulative counting;

Match paper jam detection system to realize intelligent deceleration. Paper jam stop system.

The high-speed pneumatic photoelectric paper-taking system is adopted, and the

Electric heating powder removal device (optional)

Preheat and compact the ink on the surface, which is helpful for lamination effect and speed

Remove surface dust

Chain knife (optional)