- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Small Automatic UV Coating Machine

Quality China products small automatic uv coating machine, which significantly takes into consideration of environmental protection and cost saving. It is one such revolutionary products from NEW STAR manufacturer. Shop now!

Model:SGUV-660A/740A

Send Inquiry PDF DownLoad

NEW STAR designs and manufactures innovative Small automatic uv coating machines for a wide variety of industries and materials. Reliable quality is our promsie, first-class service is our guarantee, integrity managements is our purpose, and mutual progress is our pursuit. Call now to get the latest price.

Small automatic uv coating machine

Small automatic uv coating machine is designed according to the characteristics of domestic and foreign industries. It is a UV oiled and coated equipment on the paper surface. It adopts digital printing. After being processed by this machine, it can improve the surface gloss of printed matter. It has the functions of antifouling, moisture-proof, anti fading and wear-resisting. It is controlled by PLC, 1 UV lamps and 3 IR lamps. Automatic paper feeding system is adopted to improve the glazing speed. Automatic paper receiving system is adopted to reduce manual work.

Product Parameter (Specification)

|

Model |

SGUV-660A |

SGUV-740A |

|

Max. Sheet Size |

620x760mm |

740x890mm |

|

Min. Sheet Size |

270x270mm |

270x270mm |

|

Sheet Weight |

80~500g/m2 |

80~500g/m2 |

|

Speed |

0~40m/min |

0~40m/min |

|

Power |

13.5Kw |

13.5Kw |

|

UV Lamp |

1pcsx6.5Kw |

1pcsx6.5Kw |

|

IR Lamp |

3pcsx1.2Kw |

3pcsx1.2Kw |

|

Weight |

1500kg |

2800kg |

|

Dimension |

6000x1450x1600mm |

6000x1450x1600mm |

Product Feature And Application

Small automatic uv coating machine is suitable for digital printing, color short edition fast printing, PVC business card printing, HP, indigo post press coating, water-based / solvent based ink jet printing and other printing materials. Through coating, the printed matter is bright in color, flexible and durable; It has the characteristics of moisture, heat and sun protection. It is also standard for digital post press coating.

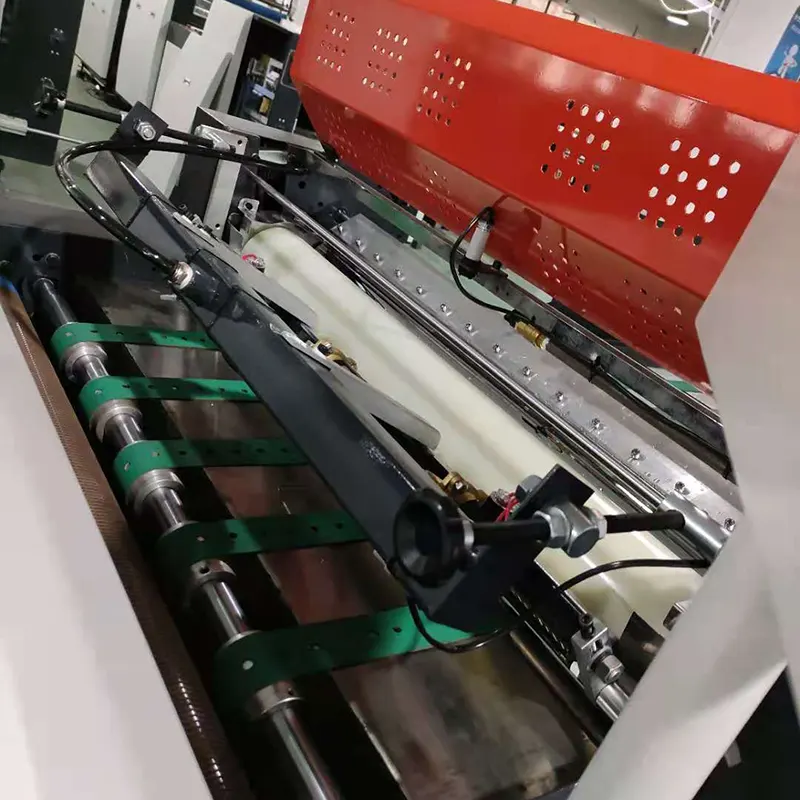

1.The main machine adopts a three-roll coating method, the diameter of the glue roller is 120mm, the diameter of the metering roller is 90mm, and the diameter of the pressure roller is 120mm to ensure that the coating surface has no lines or orange peel.。

2.Main motor adopts variable frequency speed regulating motor. Stable performance.

3.Large size touch screen control operation is simpler and more convenient, and one-key power-on can save operation time.

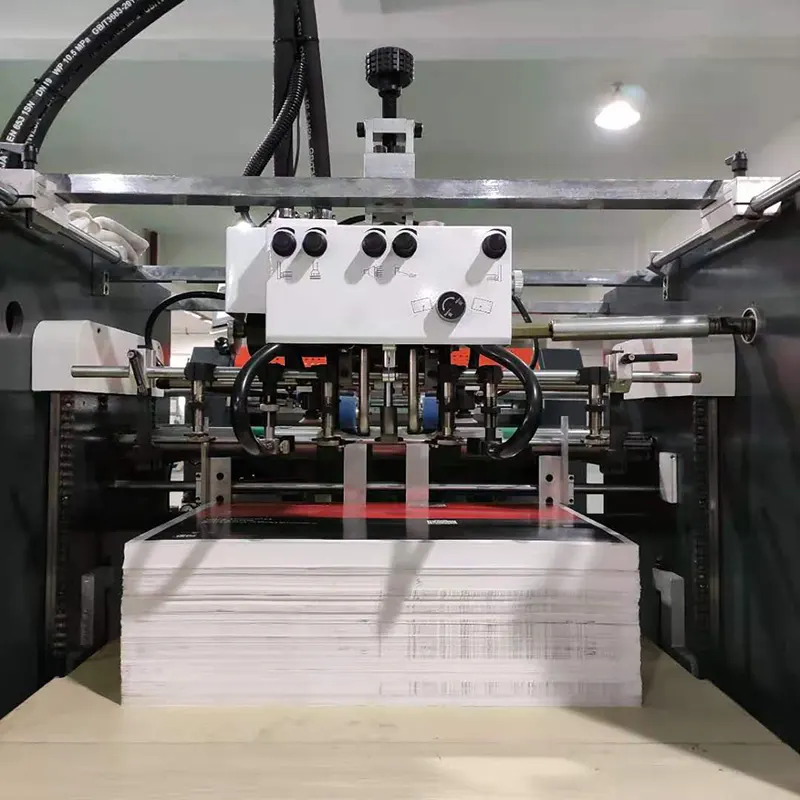

4.Equipped with a 650-type automatic medium-sized paper feeder, feeding paper is stable and reliable.

5.The unique bottom roller automatic cleaning system, double oil pan device, the lower roller is immersed in the small oil pan when working, which can effectively clean the lower roller and prevent the oil from drying out during shutdown.

6.A suction device is used in the bridge section to prevent the paper from skewing.

7.Double fuel tanks are used for fuel supply. Configure a stirring pump to separate varnish from matt oil. Reduce cleaning work during oil change.

8.Conveyor belt adopts Teflon mesh belt, underneath is equipped with suction system to make paper feeding smoother. Equipped with mesh belt automatic correction system

9.Standard configuration: 1 UV and 3 IR lamps, the oven is equipped with temperature probes, constant temperature control, saving electricity, and equipped with an automatic temperature control system.

10.The paper take-up machine runs independently and adopts pneumatic paper pat.

Product Details

|

Equipped with automatic paper feeder and paper receiver. |

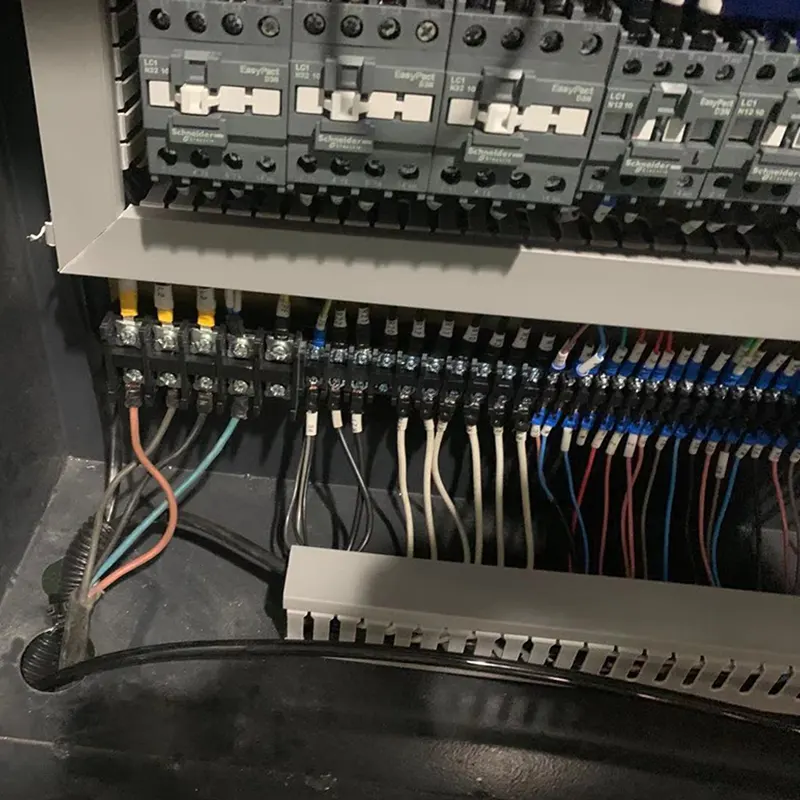

Touch screen control: the control system is controlled by PLC, and the touch screen displays the operation |

120mm coating roller to ensure that the coating surface has no lines or orange peel. |

|

|

|

|

Automatic deviation correction of Teflon conveyor belt |

A suction device is used in the bridge section to prevent the paper from skewing. |

UV curing equipment and cooling system ensure the normal service life of UV lamp. |

|

|

|