- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Wenzhou Feihua Printing Machinery Co.,Ltd founded in 2010. We are an intelligent mechanical equipment manufacturer committed to the research and development of paper surface treatment technology, personalized customization, production, sales and service.

There are more than 10000 square meters of processing workshops, with integrated production and a complete and scientific quality management system.

The factory has a professional management and technical team, first-class manufacturing process, and all manufacturing processes are implemented in accordance with high standards.

The company now has more than 20 invention patents and utility model patents for laminating machine and uv coating machine, and all products have independent intellectual property rights.

ABout US

Wenzhou Feihua Printing Machinery Co.,Ltd founded in 2010. We are an intelligent mechanical equipment manufacturer committed to the research and development of paper surface treatment technology, personalized customization, production, sales and service.

The factory is located in coastal city Zhejiang, There are more than 10000 square meters of processing workshops, with integrated production and a complete and scientific quality management system. The factory has a professional management and technical team, first-class manufacturing process, and all manufacturing processes are implemented in accordance with high standards. Continuous innovation, introduction of international cash production equipment, and long-term close cooperation with scientific research institutions to actively develop new products.

Wenzhou Feihua Printing Machinery Co., Ltd. has more than 20 years of experience in post-press equipment manufacturing, specializing in the production of laminating machines, uv coating machines, lamination films, bopp film and so on.

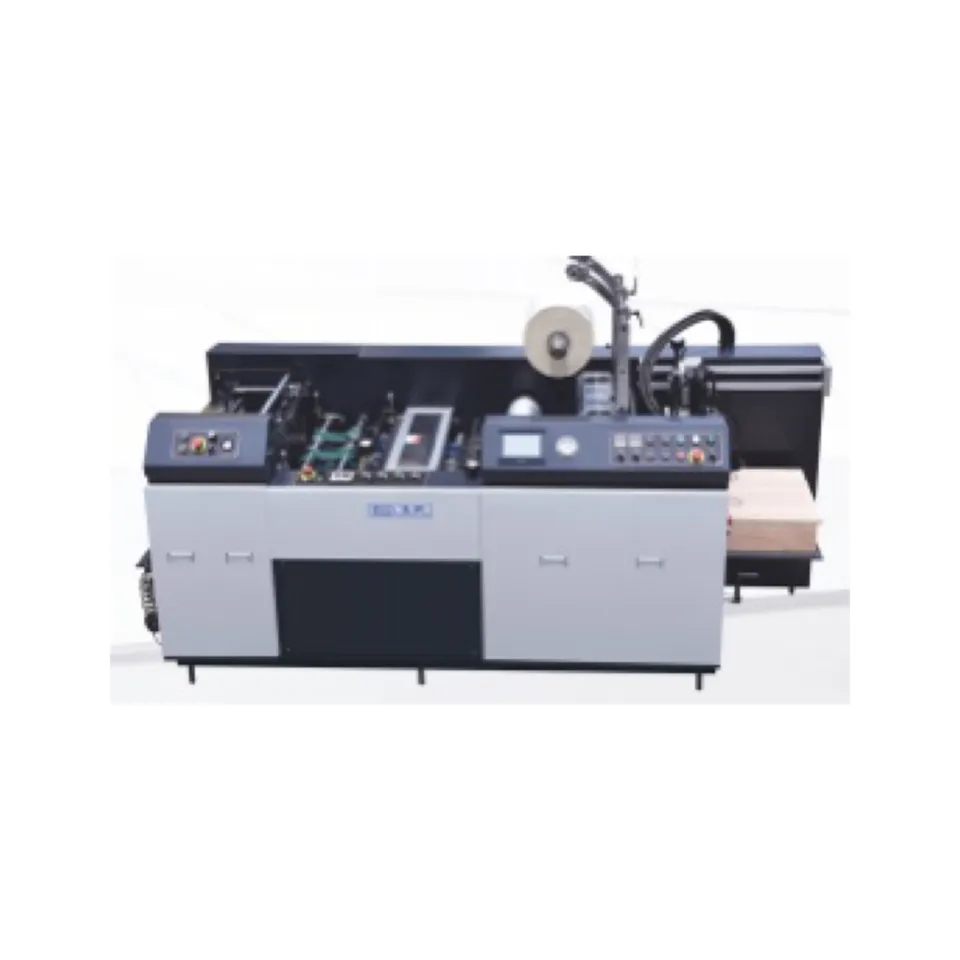

Featured Products

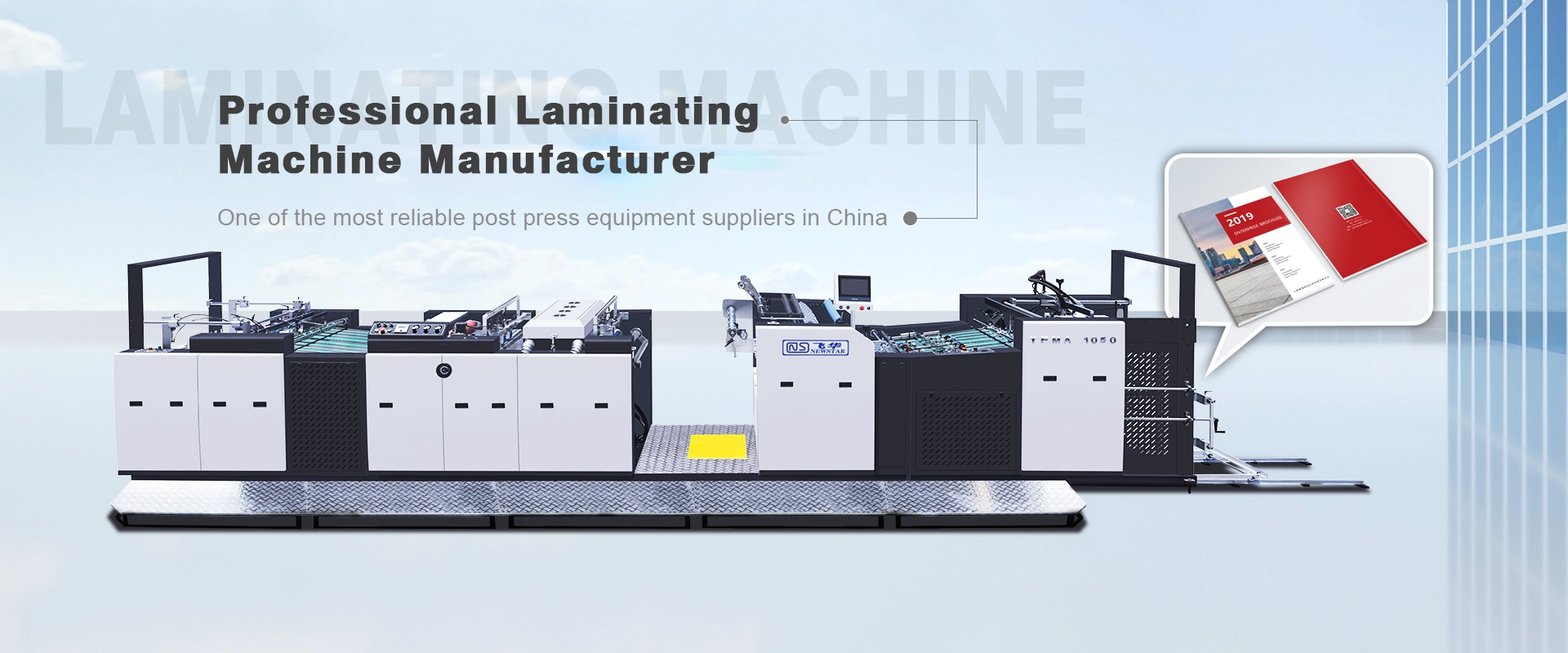

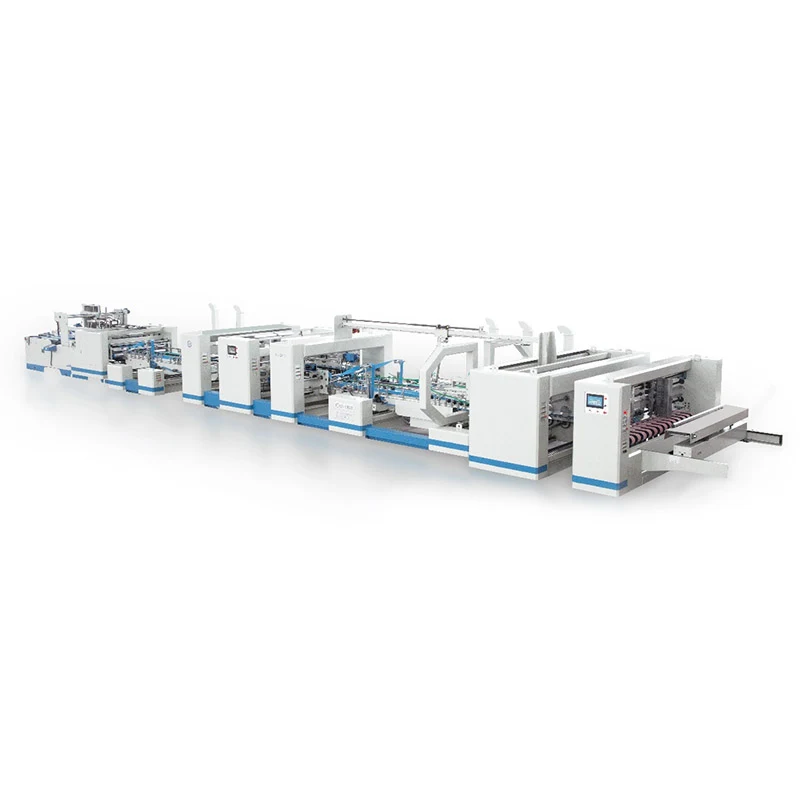

Multifunctional Automatic Laminating Machine

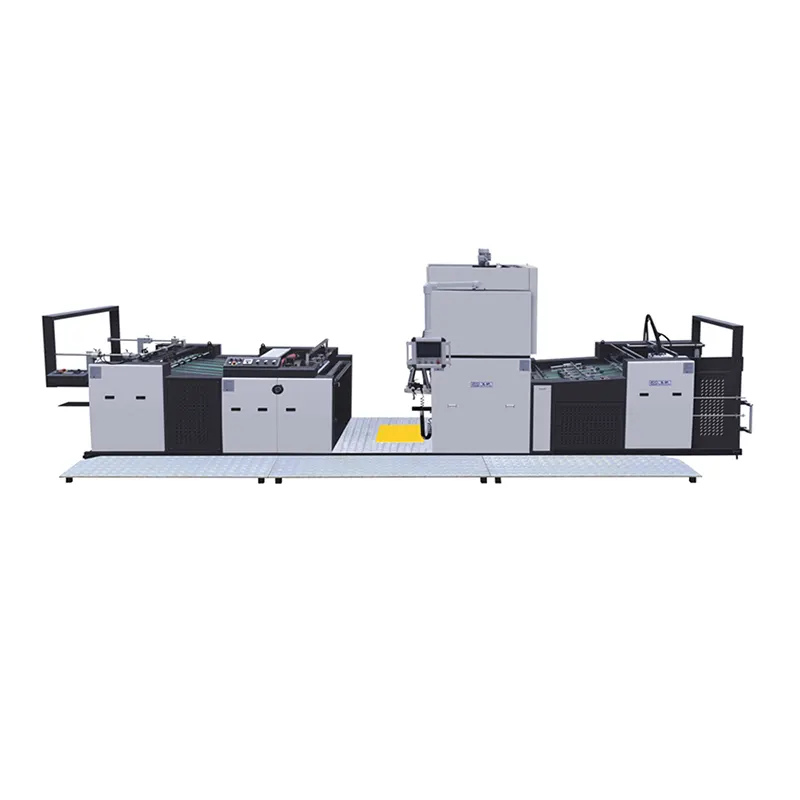

Automatic Single Head UV Coating Machine

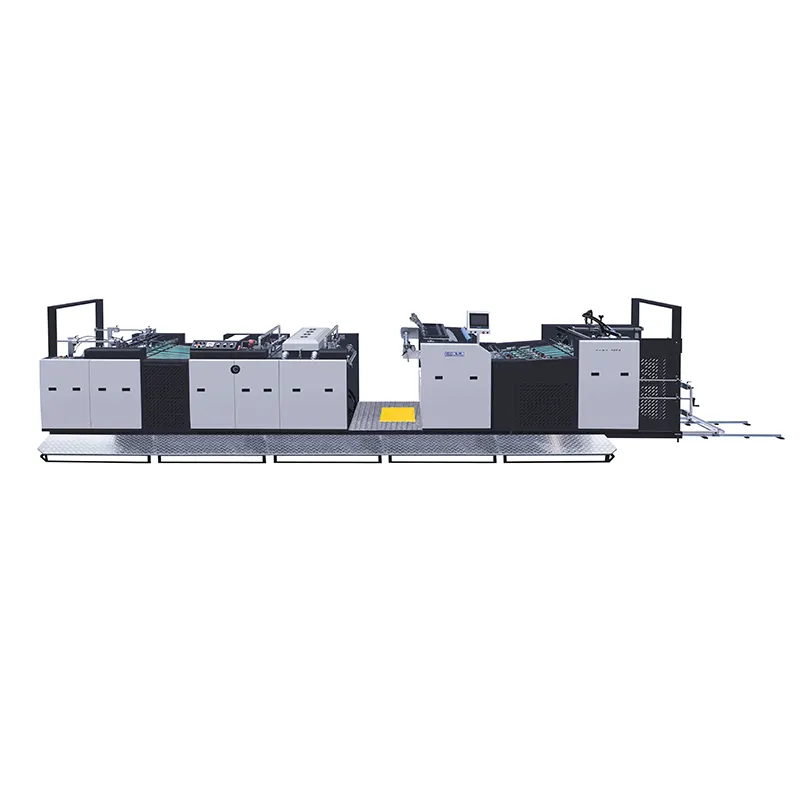

Automatic Single Face Laminating Machine

Small Automatic UV Coating Machine

Split Semi-auto Laminating Machine

One-piece Semi-auto Laminating Machine

Spot UV Varnish Coating Machine

GFMH-1300 5ply Semi-auto Flute Laminator

Semi-automatic Machine Laminator

Semi-automatic Laminating Machine ( With Embossing)

Semi-automatic Pre-coating Film Laminating Machine

Automatic Laminating Machine ( With Embossing)

News

New Products

Automatic Double Head Anilox Roller UV Coating Machine

Automatic Hot And Cold Laminating Machine

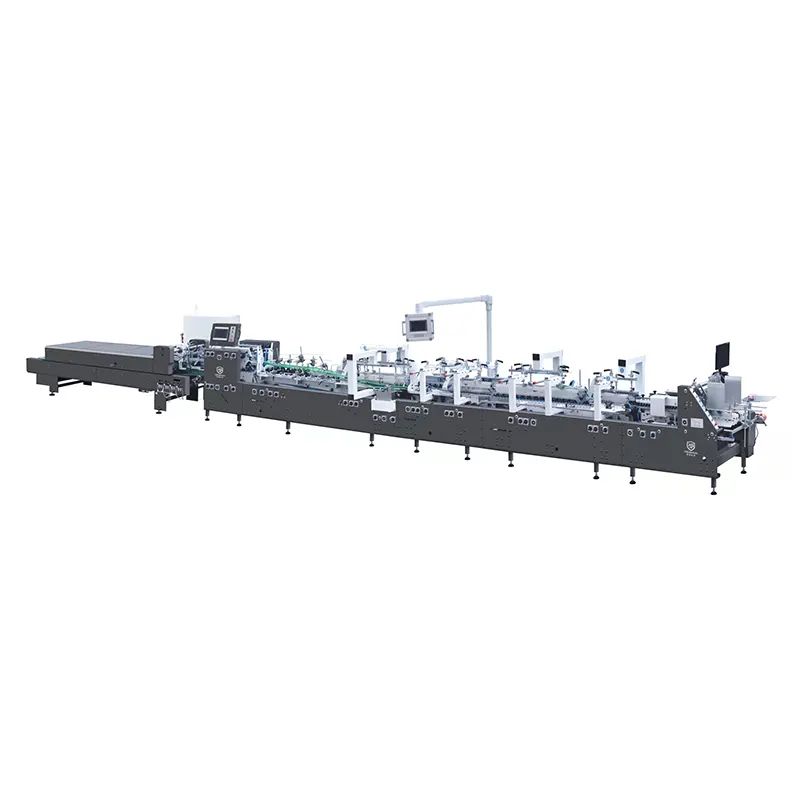

Automatic Folder Gluer Machine

Automatic Embossing Laminating Machine

Automatic Hot Stamping Machine

Automatic Window Patching Machine

Corrugated Carton Folder Gluer Machine

UV Digital Printer For Egg Cartons

Spot UV Varnish Coating Machine